Product

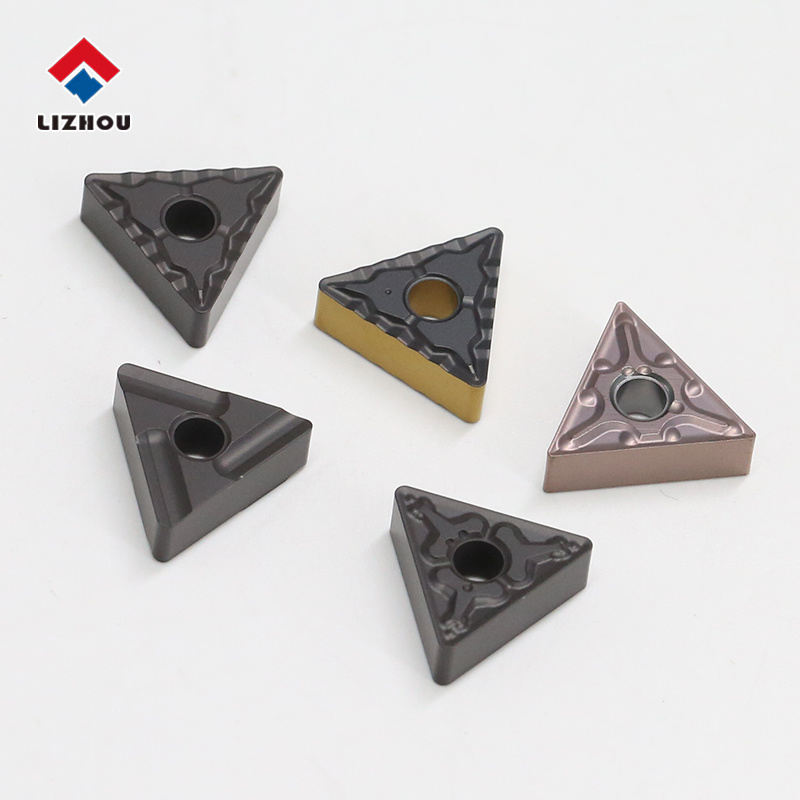

SNMG-TM\PV turning inserts

China Lizhou Hard Alloy Source Factory

Product Name:Steel Turning Inserts

Coating : CVD

Brand number:LPC202\302

Classification :

Turning insert

keyword:

lizhou

Comprehensive Guide to Carbide Turning Inserts: SNMG120408-MA, SNMG190612-TM, SNMG120409

Introduction

Carbide turning inserts are essential components in modern CNC machining and metalworking. Their performance directly influences machining efficiency, tool life, and the surface quality of the finished workpiece. Among the wide range of ISO-standard inserts, models such as SNMG120408-MA, SNMG190612-TM, and SNMG120409 have gained popularity due to their versatility and precision. Manufactured with high-quality cemented carbide substrates and advanced coatings, these inserts are designed to meet the demanding requirements of industries such as automotive, aerospace, mold making, and heavy machinery.

This article provides a comprehensive analysis of these inserts, covering advantages, ISO coding meaning, numerical parameter breakdown, applications, features, usage guidelines, and innovative technologies.

Type | Basic dimensions (mm) | Cutting data | CVD | ||||||

I.C | S | D | R | Cutting depth (mm) | Feed ( mm/tooth ) | LMP102 | LMP202 | LPC302 | |

SNMG120404-TM | 12.70 | 4.76 | 5.16 | 0.4 | 0.50-5.00 | 0.15-0.50 |

| ⚪ |

|

SNMG120408-TM | 12.70 | 4.76 | 5.16 | 0.8 | 0.50-5.00 | 0.15-0.50 |

| ⚪ |

|

SNMG120412-TM | 12.70 | 4.76 | 5.16 | 1.2 | 1.00-5.00 | 0.12-0.40 |

| ⚪ |

|

SNMG190612-TM | 19.05 | 6.35 | 7.94 | 1.2 | 1.20-5.00 | 0.17-0.55 |

| ⚪ |

|

SNMG120404R-PV | 12.70 | 4.76 | 5.16 | 1.2 | 1.50-5.00 | 0.17-0.55 |

|

| ⚪ |

SNMG120404L-PV | 12.70 | 4.76 | 5.16 | 1.2 | 1.50-5.00 | 0.17-0.55 |

|

| ⚪ |

SNMG120408R-PV | 12.70 | 4.76 | 5.16 | 1.2 | 1.50-5.00 | 0.17-0.55 |

|

| ⚪ |

SNMG120408L-PV | 12.70 | 4.76 | 5.16 | 1.2 | 1.50-5.00 | 0.17-0.55 |

|

| ⚪ |

1. Understanding Carbide Turning Inserts

Carbide inserts are replaceable cutting tools made of tungsten carbide and cobalt binder, often enhanced with coatings such as CVD (Chemical Vapor Deposition) or PVD (Physical Vapor Deposition). Compared with high-speed steel (HSS) tools, carbide inserts deliver:

Higher hardness (up to 92 HRA)

Superior wear resistance

High thermal stability

Extended tool life

Consistency in mass production machining

By using standardized insert codes such as SNMG, manufacturers and users can quickly identify the geometry, dimensions, and chipbreaker styles of each insert.

2. Breaking Down the ISO Coding (SNMG Series)

Let’s analyze the insert designation SNMG120408-MA step by step:

S = Insert shape → Square (90° corners)

N = Relief angle → 0° clearance, neutral cutting edge

M = Tolerance → ±0.05 mm, medium precision

G = Insert type → Double-sided insert with a hole, suitable for clamping

12 = Insert size → 12 mm inscribed circle

04 = Thickness → 4.76 mm (approx. 5 mm)

08 = Nose radius → 0.8 mm

-MA / -TM = Chipbreaker style → MA = Medium finishing, TM = Rough to medium machining

Similarly, SNMG190612-TM means:

19 → 19 mm size

06 → 6.35 mm thickness

12 → 1.2 mm nose radius

TM → Universal chipbreaker, suitable for steel and stainless steel

SNMG120409 means:

Same as SNMG120408, but with a 0.9 mm nose radius, offering slightly higher strength and durability at the cutting edge.

3. Product Advantages and Performance

The SNMG series inserts provide a combination of stability, wear resistance, and cutting versatility. Key advantages include:

Double-Sided Design

Each insert can be used with 8 cutting edges, maximizing cost efficiency.

High-Quality Carbide Substrate

Enhanced fracture toughness to resist chipping under heavy cutting loads.

Advanced Coatings (CVD/PVD)

Multi-layer coatings improve oxidation resistance, anti-cratering, and thermal stability.

Example: TiN, TiCN, Al2O3, TiAlN coatings.

Optimized Chipbreaker Geometry

-MA chipbreaker is designed for medium finishing with stable chip control.

-TM chipbreaker works well in medium-to-rough machining, balancing chip evacuation with tool life.

Consistent Tolerance and Precision

Manufactured under ISO standards with precise edge honing, ensuring repeatability across large production batches.

4. Applications and Usage Scenarios

The SNMG inserts are widely applied in turning, facing, and boring operations.

Industry Applications

Automotive: machining engine blocks, crankshafts, shafts, and transmission components

Aerospace: machining high-strength alloys and precision parts

Heavy Machinery: cutting cast iron and forged steel components

General Engineering: shafts, rollers, and flanges

Material Compatibility

Steel (low carbon, medium carbon, alloy steels)

Stainless steel (with -TM breaker for chip evacuation)

Cast iron

Non-ferrous metals (with adjusted cutting parameters)

Machining Operations

Finishing (using SNMG120408-MA with small nose radius for smooth surface)

Medium machining (SNMG120409 for balance between strength and finish)

Rough machining (SNMG190612-TM with larger nose radius for durability)

5. Key Features

Geometry: Square shape provides strong cutting edge support

Versatility: Compatible with a wide range of tool holders and clamping systems

Durability: Excellent wear resistance for high-speed turning

Economy: Multi-edge usage reduces cost per part

Surface Quality: Optimized chipbreaker reduces built-up edge (BUE) and improves surface finish

6. Usage Notes and Best Practices

To maximize tool performance, users should consider the following:

Cutting Parameters

Use recommended cutting speed (Vc), feed rate (f), and depth of cut (ap) depending on material.

Example: For steel, cutting speeds between 150–250 m/min with feed rates 0.1–0.3 mm/rev.

Clamping Stability

Always ensure the insert is firmly seated in the toolholder pocket to avoid vibration.

Chip Control

Select the right chipbreaker (-MA or -TM) based on machining operation.

Coolant Use

Apply cutting fluid to improve chip evacuation and reduce thermal wear, especially for stainless steel.

Tool Wear Monitoring

Watch for flank wear, nose wear, or crater wear. Replace inserts before excessive wear to maintain surface quality.

Safety Considerations

Carbide inserts are brittle; avoid impact during handling.

Use protective gloves when changing inserts.

7. Technical and Innovative Aspects

Our carbide inserts are developed with proprietary innovations:

Nano-layer CVD Coating Technology

Provides exceptional wear resistance and thermal protection, extending tool life by up to 50% compared to conventional coatings.

Advanced Powder Metallurgy Process

Ensures uniform grain size in carbide substrate, improving toughness and reducing micro-chipping.

Edge Preparation Technology

Inserts are ground and honed with micro-edge radius, balancing sharpness and strength.

OEM/ODM Customization

We provide custom chipbreaker designs, coatings, and sizes to meet industry-specific needs.

Patented Chipbreaker Design

Optimized -MA and -TM chipbreaker geometries improve chip curling and evacuation, preventing chip entanglement in automated machining lines.

8. Comparison Between Models

| Model | Nose Radius | Thickness | Application Type | Key Strengths |

|---|---|---|---|---|

| SNMG120408-MA | 0.8 mm | 4.76 mm | Medium finishing | High surface quality, chip control |

| SNMG120409 | 0.9 mm | 4.76 mm | Medium machining | Balanced wear resistance & finish |

| SNMG190612-TM | 1.2 mm | 6.35 mm | Medium-to-roughing | Stronger cutting edge, longer tool life |

9. Why Choose Our Carbide Inserts?

With 33 years of manufacturing experience, we are a leading carbide insert manufacturer providing high-performance cutting tools for global markets. Our products are:

ISO & ANSI standard compliant

Exported to over 50 countries

Supported by OEM/ODM services

Manufactured under strict QC systems with 100% inspection

By choosing our SNMG series, customers benefit from lower machining costs, longer tool life, and consistent quality in high-volume production.

Conclusion

The SNMG120408-MA, SNMG190612-TM, and SNMG120409 carbide turning inserts represent reliable solutions for a wide range of turning applications. With advanced carbide substrates, innovative coatings, and optimized chipbreaker designs, these inserts provide excellent performance in steel, stainless steel, and cast iron machining.

For manufacturers seeking precision, durability, and cost efficiency, our carbide inserts stand as an ideal choice. Whether for automotive components, aerospace parts, or heavy machinery production, these tools ensure consistent quality and high productivity.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.