Product

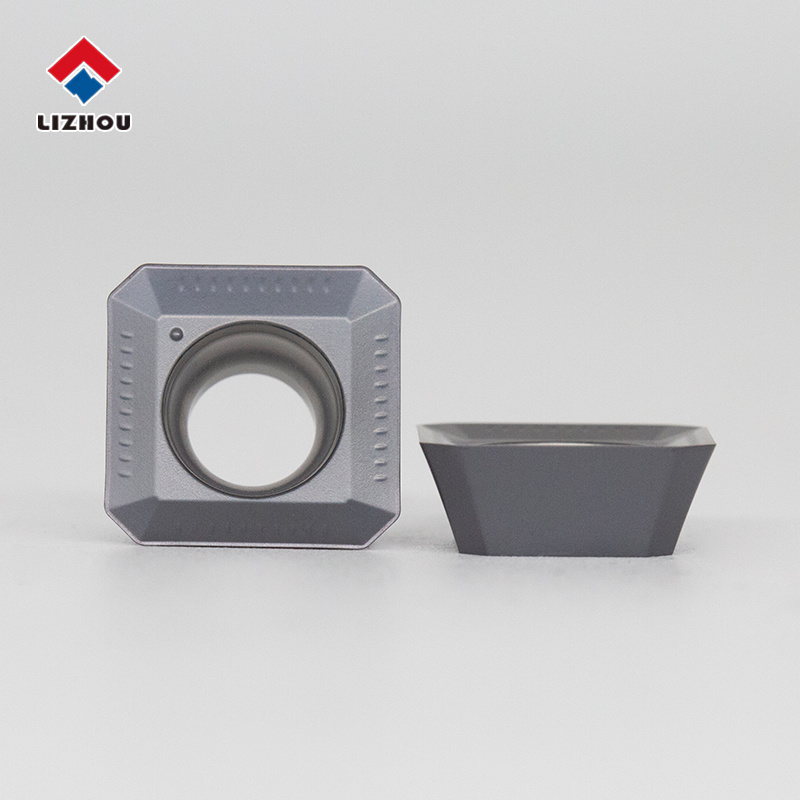

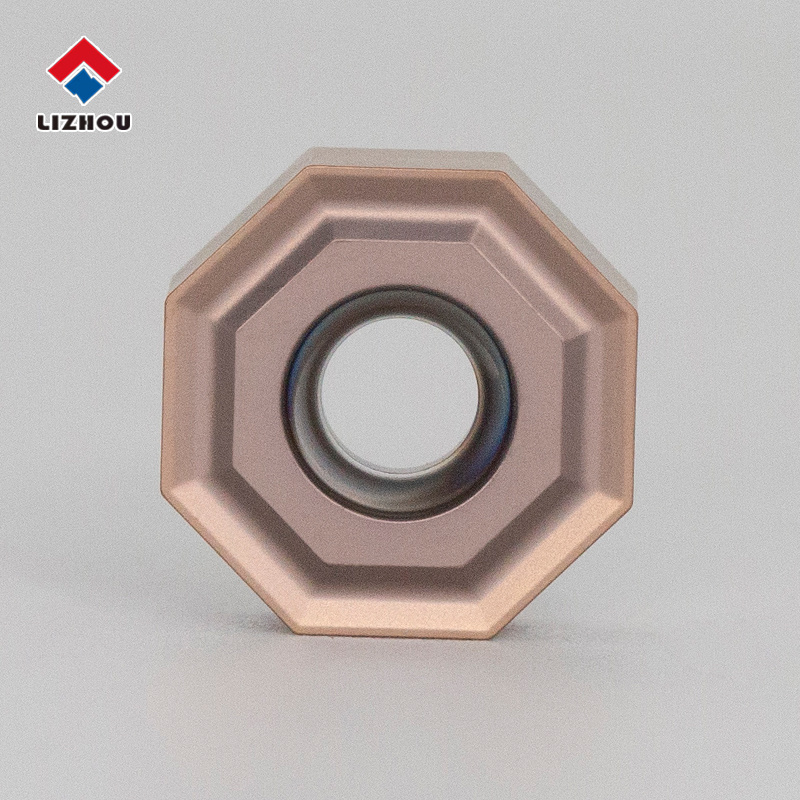

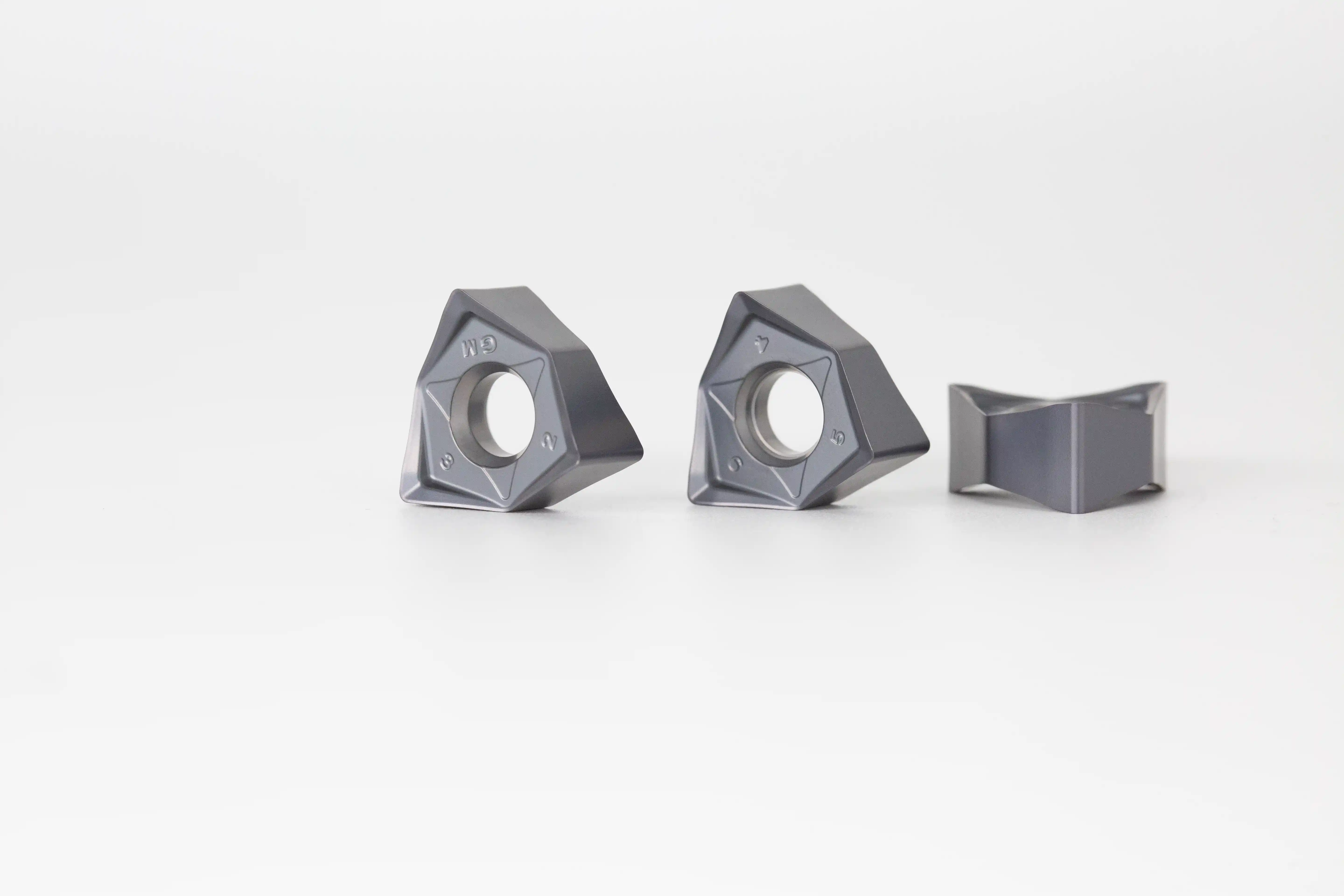

WNMU face milling inserts

China Lizhou Hard Alloy Source Factory

Product Name: Milling isnert

Coating : CVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

WNMU080608EN-GM Carbide Milling Insert – Precision, Durability, and Efficiency in One

Introduction

In today’s competitive manufacturing environment, the need for reliable, high-performance cutting tools is greater than ever. Carbide inserts have become the backbone of modern CNC milling and machining operations, enabling manufacturers to achieve superior precision, high productivity, and reduced machining costs.

Among these tools, the WNMU080608EN-GM carbide milling insert stands out for its versatile geometry, robust performance, and optimized cutting efficiency. Produced by our company, a professional hard alloy (tungsten carbide) manufacturer, this insert is engineered to meet the demands of industries such as automotive, aerospace, mold-making, general engineering, and heavy equipment manufacturing.

In this article, we provide a comprehensive technical analysis of the WNMU080608EN-GM, covering its code breakdown, performance benefits, application areas, unique features, operational precautions, and technological innovations that make it a top choice for modern machining.

1. Code Breakdown: Understanding WNMU080608EN-GM

Each character in the WNMU080608EN-GM designation provides key information about the insert’s geometry and function:

W – Shape: Trigon (80° corner angle) insert, offering strength and versatility for milling.

N – Relief Angle: 0° relief (neutral clearance), ensuring maximum cutting edge strength.

M – Tolerance: Medium tolerance, suitable for general milling with high precision.

U – Hole/Clamping: Double-sided, with chip slot and screw hole, ensuring secure clamping.

08 – Inscribed Circle (IC): 8 mm, standard for compact milling cutters.

06 – Thickness: 6 mm, providing excellent rigidity and durability.

08 – Cutting Edge Length: 8 mm, suitable for stable milling operations.

EN – Edge/Geometry: Optimized cutting edge with reinforced design for stable performance.

GM – Chipbreaker:

G = General purpose.

M = Medium cutting conditions.

This means the insert is designed for balanced chip control, reduced cutting force, and versatility across multiple materials.

2. Advantages of WNMU080608EN-GM Carbide Insert

The WNMU080608EN-GM insert offers several key advantages that make it an industry favorite:

Double-Sided Design

Provides multiple cutting edges, lowering cost-per-part.

Extends tool life and reduces tool change frequency.

High Strength & Wear Resistance

Manufactured with ultrafine tungsten carbide grain.

Excellent resistance against abrasive wear and thermal deformation.

Optimized Chipbreaker Geometry (GM)

Ensures smooth chip evacuation.

Prevents chip re-cutting, minimizing surface damage.

High Productivity

Capable of handling medium-to-high cutting speeds.

Improves machining cycle times while maintaining precision.

Versatility

Suitable for steel, stainless steel, cast iron, and alloy steels.

Performs well in both semi-finishing and finishing operations.

3. Performance Analysis

The WNMU080608EN-GM carbide milling insert demonstrates superior performance in industrial environments:

Cutting Stability: Neutral clearance angle ensures strong cutting edges, reducing breakage under load.

Tool Life: Advanced coatings (TiAlN, AlTiN, TiCN, or customized CVD/PVD layers) enhance durability.

Surface Quality: Provides a smooth surface finish, often eliminating secondary finishing.

Chip Control: GM chipbreaker handles medium depth of cut and feed rates, maintaining process stability.

Heat Resistance: Capable of dry machining under high-speed conditions.

4. Application Scenarios

The WNMU080608EN-GM carbide insert is widely applied across industries:

Automotive Industry

Machining cylinder heads, brake systems, and engine components.

Aerospace

Milling high-strength alloys with consistent precision.

Mold & Die Making

Effective in cavity milling, finishing, and contouring.

Heavy Equipment & General Engineering

Structural steel milling, large castings, and machine parts.

Energy Industry

Machining turbine housings, power generation components.

5. Features and Benefits

Trigon Shape (W) → Strong geometry, multiple cutting edges.

Neutral Relief (N) → High edge strength, longer durability.

Medium Tolerance (M) → Balances accuracy and cost-effectiveness.

Double-Sided (U) → Maximizes insert utility.

GM Chipbreaker → Reliable chip evacuation and stable cutting.

Carbide Substrate → High hardness, thermal and wear resistance.

6. Precautions and Best Practices

To maximize insert performance, users should follow these operational guidelines:

Cutting Parameters

Use recommended cutting speed and feed for each material type.

Avoid excessive depth of cut on stainless steels to prevent tool wear.

Insert Handling

Handle carefully to avoid edge chipping.

Store inserts in original protective cases.

Coolant Use

Dry machining suitable for cast iron.

Use coolant for steels and alloys to extend tool life.

Clamping Precision

Ensure correct seating in the toolholder pocket.

Avoid dirt or chips under the insert seat.

Indexing and Rotation

Replace or rotate inserts before extreme wear develops.

7. Technological and Patent Innovations

Our WNMU080608EN-GM inserts incorporate advanced manufacturing and coating technologies:

Nano-Grain Carbide Powder Metallurgy – Produces superior hardness and toughness balance.

Advanced Coatings (CVD/PVD) – Provide resistance to wear, oxidation, and heat.

Precision Edge Preparation – Enhances cutting edge strength while maintaining sharpness.

Custom OEM/ODM Service – Inserts can be tailored with specific coatings, chipbreakers, or dimensions.

Patented Chipbreaker Engineering – GM chipbreaker optimized for efficient chip evacuation and minimized vibration.

8. Why Choose Our Carbide Inserts

As a professional hard alloy manufacturer, we provide:

Direct Factory Supply – Competitive pricing without middlemen.

Strict Quality Control – Every batch tested for hardness, toughness, and coating adhesion.

Global Export Experience – Serving clients in Asia, Africa, South America, and Europe.

Engineering Support – Professional guidance for selecting cutting parameters.

Custom Solutions – Tailored inserts for industry-specific applications.

Conclusion

The WNMU080608EN-GM carbide milling insert is a high-performance, durable, and versatile cutting tool designed for modern CNC machining. With its trigon geometry, strong carbide substrate, double-sided design, and optimized GM chipbreaker, it provides long tool life, superior surface finish, efficient chip evacuation, and cost savings across a wide range of industries.

By choosing our WNMU080608EN-GM insert, manufacturers can achieve higher productivity, improved machining stability, and reduced tooling costs, all backed by the expertise of a trusted carbide manufacturer.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.