Product

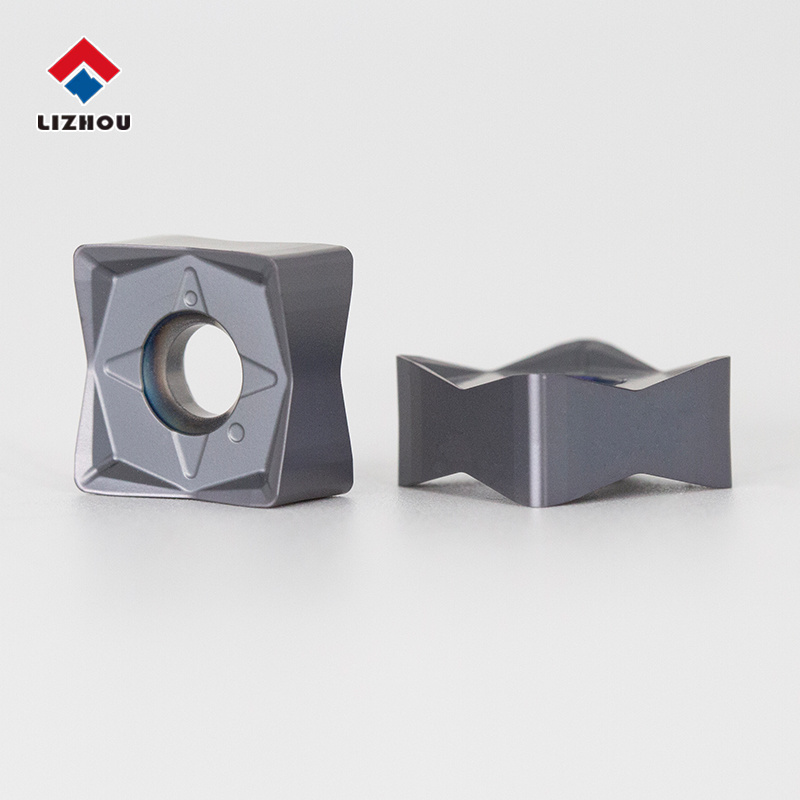

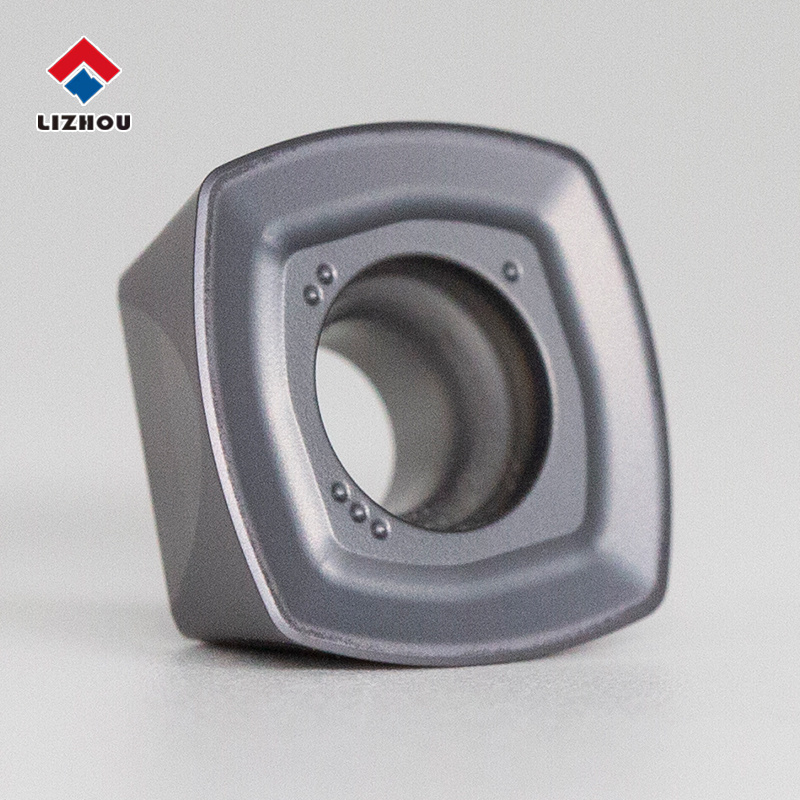

SDMT-PM rapid feed milling cutter

China Lizhou Hard Alloy Source Factory

Product Name: Fast feed milling cutter

Coating : PVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

SDMT120512-PM Carbide Milling Insert – High-Performance Precision Cutting Solution

Introduction

In modern CNC machining, cutting tools are at the heart of productivity, precision, and profitability. Among these tools, carbide milling inserts are indispensable due to their high hardness, superior wear resistance, and excellent thermal stability. For industries such as automotive, aerospace, mold-making, energy, and heavy equipment manufacturing, selecting the right insert is critical for optimizing performance and reducing costs.

One of the most reliable solutions is the SDMT120512-PM carbide milling insert, designed and manufactured by our company, a professional hard alloy (tungsten carbide) manufacturer. Engineered for versatility, stability, and efficiency, this insert provides exceptional cutting performance in a wide range of applications.

This article will give a comprehensive technical overview of the SDMT120512-PM, including code breakdown, performance benefits, applications, features, precautions, and technological innovations that distinguish our carbide inserts in the global market.

1. Code Breakdown: Understanding SDMT120512-PM

The ISO code SDMT120512-PM represents the insert’s shape, clearance, tolerance, clamping, dimensions, and chipbreaker geometry. Let’s analyze each part:

S – Insert Shape: Square-shaped insert, providing 8 usable cutting edges, maximizing tool life and reducing cost-per-part.

D – Relief Angle: 15° clearance angle, ensuring reduced cutting resistance and smoother cutting action.

M – Tolerance: Medium tolerance, offering a balance between precision and cost-effectiveness.

T – Hole/Clamping System: Single-sided insert with through-hole, compatible with secure screw or clamp systems.

12 – Inscribed Circle (IC): 12 mm, suitable for medium-to-large milling cutters.

05 – Thickness: 5 mm, providing rigidity for stability in medium-to-heavy milling operations.

12 – Cutting Edge Length: Approx. 12 mm, supporting deep and stable cuts.

PM – Chipbreaker/Geometry:

P = Steel application (optimized for roughing to finishing).

M = Medium cutting conditions (semi-finishing and finishing).

Together, “PM” indicates a universal geometry for balanced chip control, tool life, and surface finish.

This designation makes it easier for engineers and buyers to identify insert specifications and ensure correct application.

2. Advantages of SDMT120512-PM Carbide Insert

The SDMT120512-PM insert offers numerous advantages that make it an outstanding choice for modern milling:

Eight Cutting Edges

Cost-effective and resource-efficient.

Extends tool life by enabling multiple indexations.

Superior Hardness and Wear Resistance

Made from fine-grain tungsten carbide substrate.

Resistant to flank wear and built-up edge formation.

Thermal Stability

Can handle high cutting speeds without losing hardness.

Performs reliably in both wet and dry milling.

Optimized Chipbreaker Geometry (PM)

Ensures smooth chip evacuation.

Reduces cutting force, vibration, and heat buildup.

Versatile Performance

Suitable for steel, stainless steel, cast iron, and alloy steels.

Effective in semi-finishing and finishing milling.

3. Performance Analysis

The SDMT120512-PM carbide insert is designed for balanced machining performance:

Cutting Efficiency: Square geometry distributes forces evenly, ensuring longer tool life.

Chip Control: PM chipbreaker provides excellent chip curling and disposal, preventing re-cutting.

Surface Finish: Capable of achieving Ra 0.8–1.6 µm, reducing need for secondary finishing.

Tool Life: Advanced CVD or PVD coatings (TiAlN, AlTiN, TiCN) extend insert longevity.

Machining Flexibility: Works under stable as well as slightly interrupted cutting conditions.

4. Application Scenarios

The SDMT120512-PM carbide milling insert finds extensive use in industries requiring both productivity and precision:

Automotive

Engine blocks, brake components, transmission housings.

Aerospace

Machining high-strength alloys and structural components.

Mold & Die Industry

Milling of mold cavities with tight tolerances and smooth finishes.

General Engineering

Steel components, tool holders, machine parts.

Heavy Equipment

Large castings, structural steel plates, and fabricated parts.

5. Features and Benefits

Square Shape (S) → 8 cutting edges, excellent cost efficiency.

15° Relief Angle (D) → Reduced cutting resistance, enhanced sharpness.

Medium Tolerance (M) → Balanced precision and economy.

Through-hole (T) → Secure clamping and stable mounting.

PM Chipbreaker → Versatile performance for steel and medium machining.

High Durability → Extended insert life, reduced downtime.

6. Precautions and Best Practices

To achieve the best results with the SDMT120512-PM insert, follow these guidelines:

Cutting Parameters

Adjust cutting speed and feed according to material type.

High speed for carbon steels, moderate for alloy steels, reduced for stainless steel.

Clamping Accuracy

Ensure the insert is seated flat and firmly in the toolholder pocket.

Coolant Usage

Dry machining possible for cast iron.

For steels and stainless steels, coolant extends tool life and improves finish.

Insert Indexing

Rotate to unused edges before significant wear occurs.

Storage and Handling

Store in original packaging to avoid edge chipping.

7. Technological Innovations

Our SDMT120512-PM carbide inserts are manufactured using advanced technologies:

Powder Metallurgy Sintering – Ensures uniform hardness and fine grain structure.

Nano Coatings – Provide high wear resistance, thermal stability, and oxidation resistance.

Edge Preparation Technology – Prevents micro-fractures and extends tool performance.

Chipbreaker Engineering – Proprietary PM geometry for optimized chip control.

Customization (OEM/ODM) – Tailored solutions for specific customer requirements.

8. Why Choose Our Carbide Inserts

As a hard alloy manufacturer, we provide more than just cutting tools:

Factory-Direct Supply → Competitive prices with quality assurance.

Strict Quality Control → Hardness, toughness, and coating adhesion tested for every batch.

Engineering Support → Professional recommendations on cutting parameters.

Global Experience → Serving clients across Asia, Africa, South America, and Europe.

Customized Solutions → Coatings, geometries, and sizes tailored to your industry.

Conclusion

The SDMT120512-PM carbide milling insert is a reliable, versatile, and cost-effective solution for modern machining. With 8 cutting edges, strong carbide substrate, advanced coatings, and optimized PM chipbreaker geometry, it delivers superior performance across automotive, aerospace, mold-making, and general engineering industries.

By choosing our SDMT120512-PM insert, manufacturers benefit from extended tool life, improved surface finish, reduced machining costs, and higher productivity.

As a trusted carbide manufacturer, we combine precision engineering, advanced material science, and industry expertise to deliver cutting tools that meet the toughest machining challenges.

Frequently Asked Questions

Q1: What is the minimum order quantity (MOQ)? Do you support mixed batches?

The standard MOQ is 10 boxes (10 pieces per box). Some suppliers support mixed model procurement, which needs to be negotiated in advance.

Q2: How long is the delivery time? Is there any stock?

The standard delivery time is 15-30 days (depending on the coating customization requirements). Conventional models usually have stock, special coatings need to be pre-ordered.

Q3: Do you provide free samples? Who bears the freight?

The supplier provides one box of samples, and the freight is usually borne by the buyer

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.