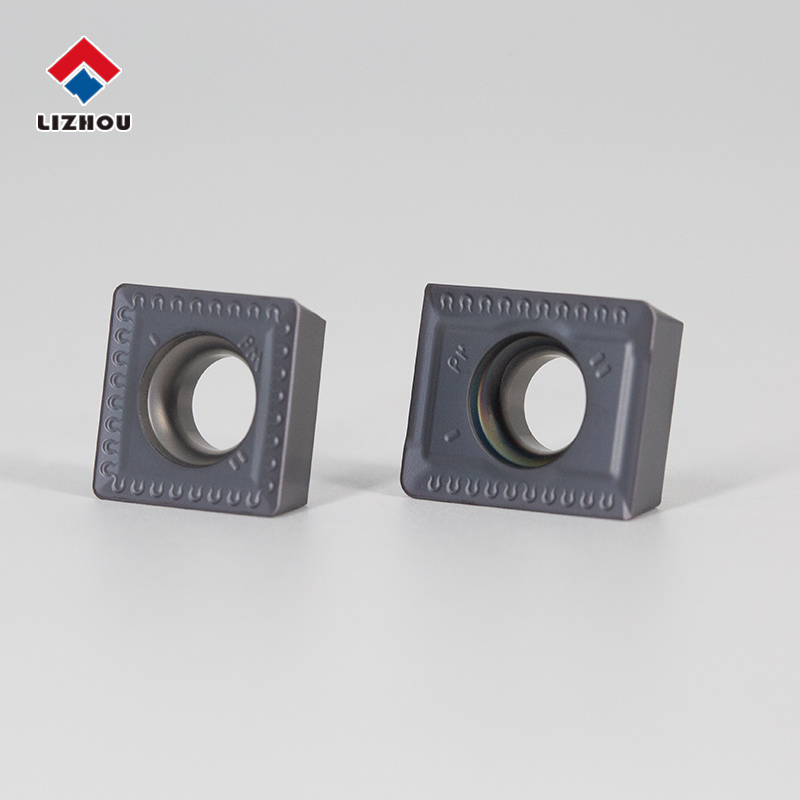

APKT150412

Product

APKT150402-Corn milling cutter

China Lizhou Hard Alloy Source Factory

Product Name: Milling Insert

Coating : PVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

APKT150412-PM Carbide Milling Insert – Premium Corn Milling Insert for High-Performance Machining

Introduction

The demand for precision, durability, and cost-efficiency in modern machining has made carbide milling inserts essential in industries such as automotive, aerospace, mold-making, and general engineering. Among the most versatile solutions is the APKT150412-PM carbide milling insert, also known as a corn milling insert.

As a professional tungsten carbide (hard alloy) manufacturer, we specialize in developing cutting-edge solutions designed to withstand extreme machining conditions. The APKT150412-PM insert is engineered to deliver superior chip control, longer tool life, and excellent surface finishes, making it a top choice for roughing, semi-finishing, and finishing operations.

1. Code Breakdown: Understanding APKT150412-PM

The designation APKT150412-PM follows ISO standards for insert classification. Each part of the code defines a specific feature:

A – Insert shape: Parallelogram shape, optimized for stable cutting in milling.

P – Relief angle: 11° clearance angle, ensuring effective chip evacuation and reduced cutting forces.

K – Tolerance: Indicates medium-precision classification, balancing accuracy with cost efficiency.

T – Type of insert: Refers to single-sided inserts with a hole for secure clamping.

15 – Insert size: 15 mm cutting edge length, suitable for medium to heavy-duty milling.

04 – Thickness: 4.76 mm, providing rigidity and strength.

12 – Corner radius: 1.2 mm, designed for stable cutting edges and extended tool life.

PM – Chipbreaker type:

P = Steel machining focus.

M = Medium cutting conditions.

Together, PM refers to a universal medium chipbreaker for versatile use.

This breakdown highlights the APKT150412-PM as a robust, high-performance corn milling insert engineered for precision and versatility.

2. Advantages of APKT150412-PM Carbide Inserts

High Cutting Performance

Sharp cutting edges reduce cutting force and vibration.

Capable of high-feed and stable machining in various conditions.

Excellent Chip Control

The PM chipbreaker ensures smooth chip evacuation, preventing tool damage and improving surface quality.

Extended Tool Life

Manufactured from ultrafine-grain carbide substrate, offering high hardness and wear resistance.

Advanced coating technology enhances heat resistance and oxidation stability.

Cost Efficiency

Multi-edge design maximizes usage per insert.

Reduced downtime due to longer insert life.

Versatility

Works across a wide range of materials, including steel, stainless steel, and cast iron.

Suitable for both roughing and finishing applications.

3. Performance Analysis

The APKT150412-PM insert is designed to optimize performance under demanding conditions:

Material Substrate: Hard alloy base material with fine carbide grain structure ensures toughness and durability.

Coating Options: PVD (TiAlN, AlTiN) or CVD coatings (TiCN, TiN) enhance performance in high-heat environments.

Geometry: Unique parallelogram shape supports stable cutting and right-angle milling.

Chipbreaker Design (PM): Provides efficient chip evacuation in medium-depth cuts.

Cutting Parameters:

Feed rate: 0.15 – 0.45 mm/tooth (depending on workpiece).

Cutting speed: 150 – 300 m/min for steel applications.

4. Application Scenarios

The APKT150412-PM carbide corn milling insert is widely used across industries:

Automotive Industry

Cylinder heads, engine blocks, and transmission housings.

Aerospace Industry

Stainless steel and titanium alloy parts requiring precision milling.

Mold & Die Industry

Cavity milling, slotting, and complex contouring operations.

General Engineering

Slotting, facing, and profiling in steel and cast iron.

Heavy Machinery

Structural components requiring medium-to-heavy material removal.

5. Key Features and Benefits

Parallelogram Design (APKT Series) → Stable cutting geometry.

Universal Medium Chipbreaker (PM) → Versatile chip control across steels and stainless steels.

Tough Carbide Substrate → Combines hardness and toughness.

Precision Edge Preparation → Enhances surface finish and reduces cutting forces.

Wide Compatibility → Suitable for various CNC milling cutters, especially corn milling cutters.

Extended Tool Life → Coatings and geometry reduce wear and improve reliability.

6. Precautions and Best Practices

Cutting Parameters

Adjust feed and speed according to workpiece hardness.

Avoid excessive depth of cut in stainless steel.

Insert Handling

Store inserts properly to avoid chipping.

Avoid direct contact with edges during handling.

Tool Clamping

Ensure correct seating in the toolholder.

Clean pockets before inserting to prevent misalignment.

Coolant Use

Use coolant in stainless steel or high-temperature alloys.

Dry machining suitable for cast iron.

Indexing Strategy

Rotate inserts before excessive wear develops.

This ensures consistent performance and prevents tool breakage.

7. Technological and Patent Innovations

Nano-Grain Carbide Substrate – Enhances both toughness and hardness.

Advanced Coatings (PVD/CVD) – Improve wear resistance and performance under heat.

Optimized Chipbreaker Design (PM) – Balances chip evacuation with surface finish.

OEM/ODM Customization – Inserts can be tailored for specific machining needs.

Innovative Edge Preparation – Reduces micro-chipping and extends tool life.

8. Why Choose Our Carbide Inserts

As a trusted hard alloy manufacturer, we provide:

Direct Factory Supply – Competitive pricing and guaranteed quality.

Strict Quality Assurance – Inserts undergo rigorous inspections.

Technical Support – Expert recommendations for cutting conditions.

Global Reach – Widely used in Asia, South America, Africa, and Europe.

Continuous R&D – Dedicated innovation in coatings, substrate, and chipbreaker design.

Conclusion

The APKT150412-PM carbide corn milling insert is a versatile, high-performance solution for CNC milling. Its parallelogram geometry, PM chipbreaker, and durable carbide substrate ensure excellent chip evacuation, long tool life, and superior surface quality.

By choosing our APKT150412-PM inserts, manufacturers gain cost savings, improved productivity, and reliable machining performance backed by the strength of a professional carbide insert manufacturer.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.