Blog

Turning inserts: carbide tools and lathe tool factory

As a core manufacturer of cemented carbide tools, we, Lizhou, focus on innovation in the turning field to Carbide Insert Lathe Tools (Cemented carbide lathe inserts) 、 Cutting Carbide Inserts (Cutting cemented carbide inserts) 、 Carbide Cutter Inserts (Cemented carbide inserts) 、 Inserts for Turning (Turning inserts), four major product matrices, providing global users with precisely matched metal processing solutions.

The advantages of our turning inserts ( Inserts for Turning ) are:

1. Ultra-hard matrix, challenging extreme processing

Using nanocrystalline ( 0.5μm grade) cemented carbide substrate, the hardness reaches 93.5HRA ,improved anti-crushing performance 60%:

The single-edge life of rough turning cast iron exceeds 120 minutes

The surface roughness of precision turning quenched and hardened steel ( HRC55 ) remains stable at Ra0.8μm

2. Intelligent coating, uncompromising high temperature

PVD+PCVD composite coating technology, 8μm gradient protective layer is achieved:

Anti-oxidation temperature exceeds 1100℃

The cutting speed when turning stainless steel can reach 350m/min

The occurrence rate of built-up edge in titanium alloy processing is reduced 75%

3. Geometric revolution, efficiency multiplier

• Double-sided 16 cutting edge design :Utilization rate improvement 200% ,reducing the cost of single-piece processing

• 0.02mm Grade cutting edge blunting :Eliminate microscopic chipping, size fluctuation when precision turning copper parts ≤5μm

• Adaptive chip breaker :From continuous chips to C type chips are matched with one click, and the chip flow rate is improved 90%

Four core application scenarios

Typical Case

|

Performance

|

|

|---|---|---|

Automotive Manufacturing

|

Turning of engine crankshaft journals

|

Single blade processing 120 pieces, CPK value ≥1.67

|

Aerospace

|

Precision turning of titanium alloy shells

|

Surface roughness Ra0.4μm ,straightness 0.01mm/m

|

Energy Equipment

|

Turning of the overlay weld layer of nuclear power valves

|

Continuous processing without chipping 4 hours, temperature stability ±15℃

|

Medical Devices

|

Turning of cobalt-chromium alloy bone nails

|

Achieve φ0.8mm microstructure processing, tolerance ±0.005mm

|

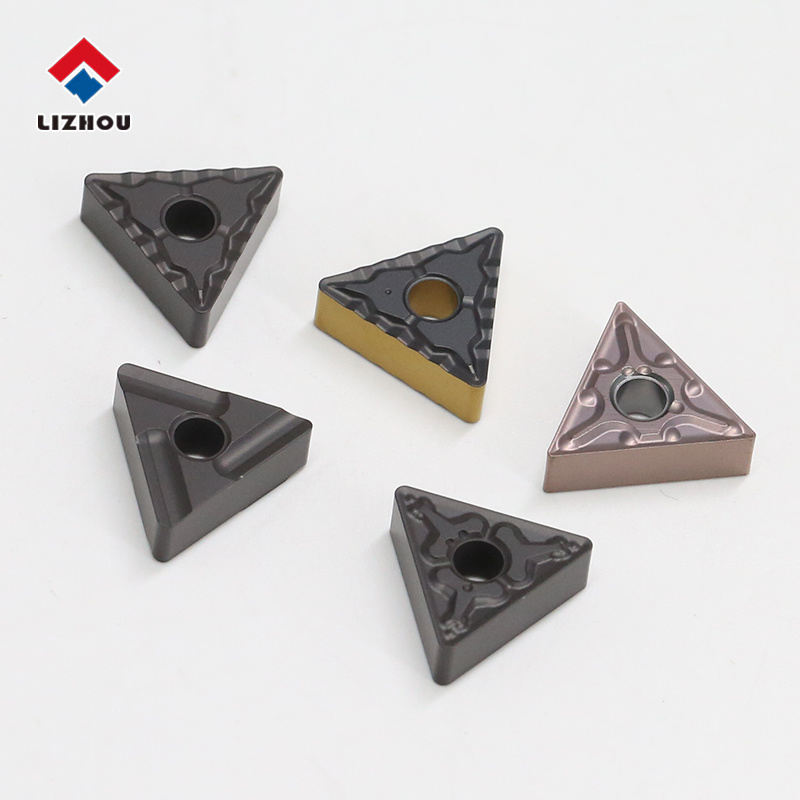

Recommended high cost-effective turning inserts ( inserts for turning )

1. TNMG160404-PV\43 Triangular insert

Features :Double-sided 6 cutting edge design, matched with TiAlN coating ( PV technology), high temperature resistance up to 800°C ,suitable for high-speed continuous cutting.

Applicable materials :Semi-finishing to finishing of stainless steel, alloy steel, and cast iron.

Advantages :0.4mm The tip radius can improve the surface roughness ( Ra≤1.6μm ),excellent economy.

2. SNMG120408-TM\HX Square cutter

Features :Double-sided 8 Blade structure, using multi-layer composite coating ( TM technology), strong anti-chipping performance, specially designed for heavy-duty intermittent cutting.

Applicable materials :Rough machining of forgings and castings, especially good at high-hardness alloy steel.

Advantages :12mm The inscribed circle diameter takes into account both cutting depth and rigidity, and the feed rate can reach 0.5mm/rev。

Applicable materials and optimized processing parameters

No matter what you are processing Stainless steel 、 Alloy steel 、 Cast iron or High temperature alloy ,choose the appropriate Carbide cutter inserts ( carbide cutter inserts ) and adjusting the parameters is crucial:

Stainless steel :

Recommended cutter : TNMG160404-PV\43 (Fine machining) / CNMG120408-MP (Rough machining).

Parameter suggestions :Cutting speed 120-180m/min ,Feed rate 0.1-0.3mm/rev ,Use high-pressure coolant to reduce built-up edge.

Cast iron :

Recommended cutter : SNMG120408-TM\HX (Rough machining) / DNMG150608-KM (Fine machining).

Parameter suggestions :Cutting speed 80-150m/min ,Large cutting depth ( 3-5mm ) prioritize efficiency, dry cutting or minimal lubrication.

High temperature alloy :

Recommended cutter :Special coated blades (such as AlCrN coating), tip radius ≤0.2mm 。

Parameter notes :Reduce cutting speed to 50-80m/min ,Small cutting depth ( 0.1-0.3mm ) avoid thermal stress concentration.

Whether you need a general-purpose Cutting Carbide Inserts ,or a specialized lathe Inserts for Turning ,we use 32 years of carbide R&D experience to help you break through processing bottlenecks!

next page

Recommended products