Blog

Li Zhou cemented carbide turning blade model comparison table

Lizhou cemented carbide Turning insert model cross-reference table

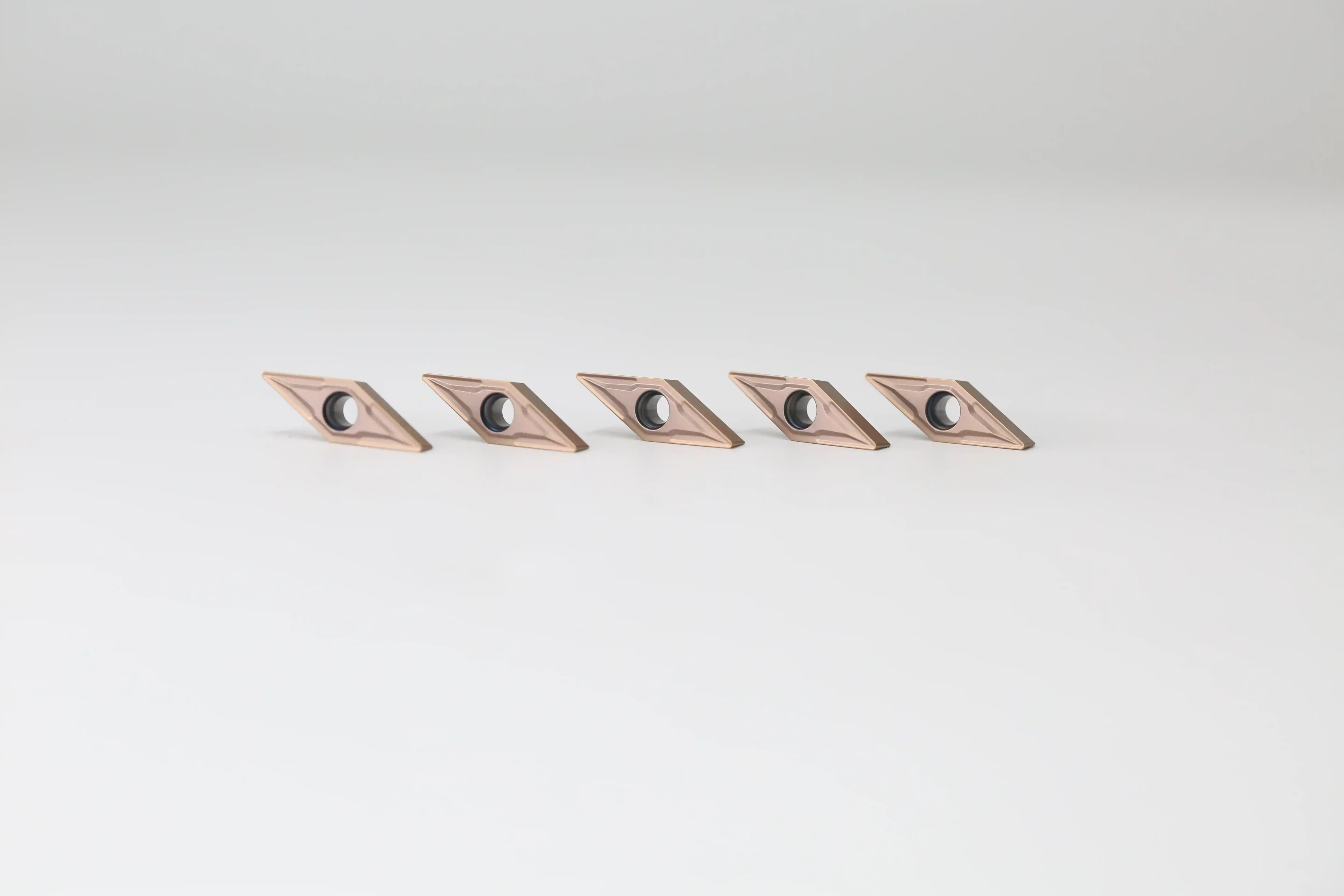

As a professional manufacturer specializing in cemented carbide for many years, Lizhou understands that the core of efficient processing lies in the precise matching of tools.

To help you quickly locate the ideal turning insert solution, we have carefully created based on industry needs Three core chart tools —— Cemented carbide insert diagram, insert identification chart and lathe insert chart, simplifying the complex selection process.

1. Lock the processing range

2. Precise identification

Are you confused by the alphanumeric combination of the insert model code? Our Lizhou cemented carbide insert identification chart ( Carbide Insert Identification Chart ).

This chart systematically analyzes ISO Standard coding rules, decomposing key information such as material grade, edge treatment, and tolerance grade bit by bit.

For example, the code “CNMG120408-MA” In “C” Represents the insert shape, “N” Indicates the back rake angle, “MA” Points to the double-sided chip breaker design

3. Strengthen process matching

For the special needs of turning, Lizhou lathe insert chart ( Lathe Insert Chart ) Lizhou further refines the application scenarios.

The chart is classified according to processes such as external turning, end face cutting, and grooving, combined with spindle speed, feed rate, and cutting depth parameters, to recommend the optimal insert - Tool holder combination scheme.

For example, under high-intensity intermittent cutting conditions, the chart will prioritize guiding you to choose a negative insert with a reinforced cutting edge to ensure processing stability. In addition, the chart also indicates coolant adaptation recommendations to help you comprehensively optimize processing conditions.

Recommended products