Product

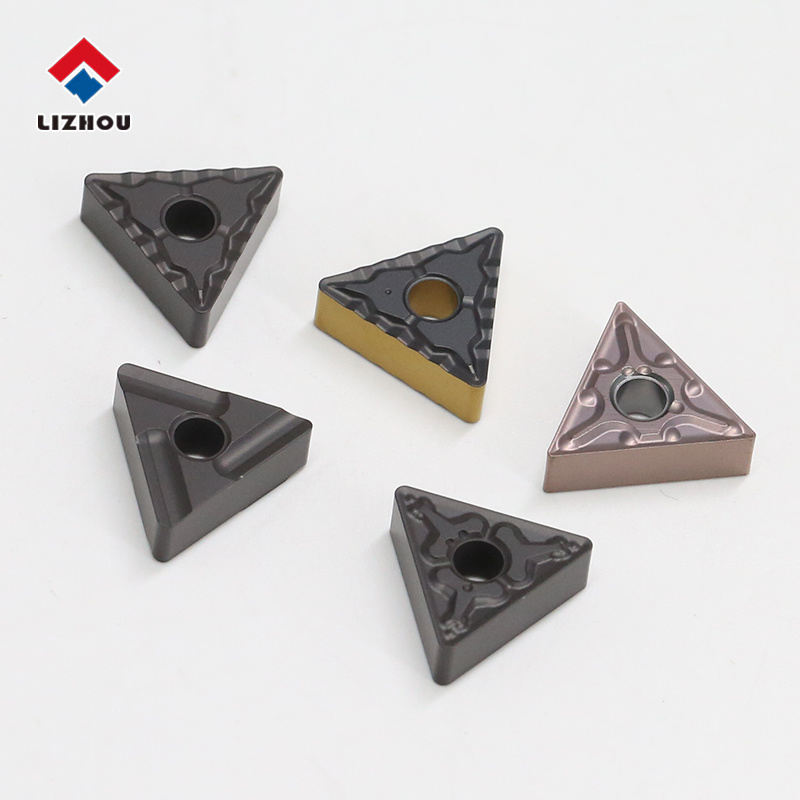

TNMG-HK cast iron turning insert

China Lizhou Hard Alloy Source Factory

Product Name:Cast Iron Turning Inserts

Coating : CVD

Brand number:LKC202\302

Classification :

Turning insert

keyword:

lizhou

TNMG160408-HK Carbide Turning Inserts: Precision, Performance, and Durability

Introduction

In modern machining, efficiency and precision are not optional—they are essential. For industries such as automotive, aerospace, energy, and general engineering, high-quality cutting tools determine productivity, accuracy, and profitability. Among these tools, carbide turning inserts stand out for their balance of durability, cutting efficiency, and cost-effectiveness.

One of the most widely used types is the TNMG160408-HK carbide insert, engineered for high-performance turning applications. Manufactured by our company with over 33 years of expertise in carbide tooling production, this insert combines advanced coating technologies, optimized chip breakers, and carefully engineered geometry to deliver exceptional results in steel, stainless steel, and cast iron machining.

This article explores the advantages, technical meaning of TNMG160408-HK, parameters, applications, features, usage precautions, and innovative technology behind this product.

Type | Basic Dimensions (mm) | Cutting Data | CVD | ||||||

I.C | S | D | R | Cutting Depth (mm) | Feed ( mm/tooth ) | LKC202 | LKC302 | LKC352 | |

TNMG160408-HK | 9.525 | 4.76 | 3.81 | 0.8 | 0.80-4.10 | 0.15-0.45 | ⚪ |

|

|

TNMG160412-HK | 9.525 | 4.76 | 3.81 | 1.2 | 1.20-4.10 | 0.25-0.65 | ⚪ |

|

|

TNMG160408 | 9.525 | 4.76 | 3.81 | 0.8 | 2.50-12.0 | 0.25-0.65 |

| ⚪ |

|

TNMG160412 | 9.525 | 4.76 | 3.81 | 1.2 | 3.50-12.0 | 0.35-0.85 |

| ⚪ |

|

What Does TNMG160408-HK Mean?

Every turning insert designation follows ISO and ANSI coding standards, where each letter and number provides critical information about the insert’s shape, clearance, tolerance, dimensions, and chip breaker type. Let’s break it down:

T – Insert Shape: Triangle (60°)

N – Relief Angle: 0° relief (neutral clearance, double-sided insert, providing higher strength and economy)

M – Tolerance Class: Medium tolerance, suitable for general-purpose precision turning

G – Hole Type: Double-sided insert with a hole and chip groove

16 – Insert Size: 16 mm inscribed circle

04 – Thickness: 4.76 mm (approx.)

08 – Corner Radius: 0.8 mm, providing a balance between strength and surface finish

HK – Chip Breaker Style:

H: Optimized for stainless steel and ductile materials, designed for stable chip control.

K: Fine-tuned cutting geometry for low cutting forces and heat resistance.

In short:

The TNMG160408-HK is a triangular, neutral-clearance, double-sided carbide insert with a medium tolerance and 0.8 mm corner radius, equipped with an HK chip breaker for stainless steel and steel machining.

Advantages of TNMG160408-HK Carbide Inserts

1. Superior Wear Resistance

Manufactured from premium-grade tungsten carbide substrate, the insert provides outstanding hardness and resistance to abrasive wear, extending tool life even in high-speed turning.

2. High-Temperature Performance

The advanced PVD or CVD coating (TiAlN, Al2O3, or multi-layered nano-composite coatings) ensures thermal stability, preventing rapid tool wear during continuous cutting of stainless steel or alloy steels.

3. Optimized Chip Control

The HK chip breaker is engineered for stainless steel applications, ensuring smooth chip evacuation, reducing built-up edge formation, and maintaining consistent cutting forces.

4. Cost Efficiency

The double-sided design (0° relief angle) allows the use of six cutting edges per insert, maximizing tool economy without compromising strength.

5. Versatility

Suitable for semi-finishing and finishing operations across a wide range of workpiece materials, including:

Stainless steel (304, 316, duplex, etc.)

General steels (carbon steel, alloy steel)

Cast iron

Technical Parameters of TNMG160408-HK

| Parameter | Value / Meaning |

|---|---|

| Insert Shape (T) | Triangle, 60° |

| Clearance (N) | 0° (neutral, double-sided) |

| Tolerance (M) | Medium accuracy |

| Hole Type (G) | With chip groove and fixing hole |

| Size (16) | 16 mm inscribed circle |

| Thickness (04) | 4.76 mm |

| Corner Radius (08) | 0.8 mm |

| Chip Breaker (HK) | Stainless steel optimized |

Applications and Use Cases

1. Automotive Industry

Machining engine components (crankshafts, shafts, gears)

Stainless steel exhaust and precision shafts

2. Aerospace

Turning stainless steel turbine rings and high-strength alloys

Machining titanium-based secondary components

3. General Engineering

Steel bar and pipe turning

Production of fasteners, fittings, and precision machine parts

4. Oil & Gas / Energy

Machining stainless steel valves, pump housings, and connectors

Role and Function in Machining

Semi-Finishing & Finishing: Designed for removing moderate material stock while achieving excellent surface finish.

Stable Cutting Edge: The triangular shape and 0.8 mm radius balance sharpness with strength, ensuring reliable performance.

Chip Formation Control: Reduces vibration, ensures smoother surfaces, and prevents re-cutting of chips.

Key Features of TNMG160408-HK Inserts

Double-Sided Economy – Six cutting edges per insert reduce cost per part.

Strong Edge Strength – Neutral 0° relief increases insert stability.

High Surface Quality – Optimized rake geometry achieves Ra < 1.6 μm finish.

Coating Innovation – CVD/PVD multi-layered coatings extend tool life by up to 50%.

Compatibility – Fits standard ISO tool holders (TNMG tool holders).

Usage Precautions

To maximize performance and lifespan of TNMG160408-HK inserts, follow these best practices:

Cutting Speed (Vc): Adjust based on material — 150–250 m/min for stainless steel.

Feed Rate (f): 0.1–0.3 mm/rev for finishing, 0.3–0.5 mm/rev for semi-finishing.

Depth of Cut (ap): 0.2–2.5 mm depending on operation.

Coolant Usage: Recommended when machining stainless steel to control heat and avoid built-up edges.

Tool Clamping: Ensure rigid setup to reduce chatter.

Insert Indexing: Rotate or flip inserts before excessive flank wear to maximize usage.

Technological Innovations & Patents

Our hard alloy manufacturing technology integrates:

Nano-Coating Technology – Advanced TiAlN and AlTiN coatings improve oxidation resistance and wear life.

Gradient Substrate Technology – Ensures a tough core with a hard surface, combining fracture resistance with cutting-edge hardness.

Precision Grinding & Edge Honing – Guarantees uniform cutting edges with minimal deviation for consistent performance.

Chip Breaker Innovation (HK) – Patented chip groove design reduces cutting resistance, improves heat dissipation, and ensures chip control across a wide speed range.

Green Manufacturing Process – Eco-friendly coating and sintering methods reduce environmental impact.

Why Choose Our TNMG160408-HK Inserts?

33 Years of Manufacturing Experience – Trusted by industries worldwide.

OEM/ODM Support – Custom solutions tailored to specific customer needs.

Quality Assurance – ISO-certified production with rigorous testing.

Competitive Pricing – Factory-direct supply with cost-effective solutions.

Global Export Expertise – Products supplied to over 40 countries.

Frequently Asked Questions (FAQ)

Q1: Is it suitable for stainless steel machining?

It is recommended to use HM material (optimized for stainless steel adhesion), HK material is more suitable for steel and cast iron.

Q2: Does the insert have a wiper?

This model is a general-purpose model. If a wiper is required, please select a model with a suffix (e.g., TNMG160408-HK).

Q3: What is the minimum order quantity (MOQ)?

Standard MOQ: 10 boxes (100 pieces), sample orders are supported (minimum order quantity 1 box).

Conclusion

The TNMG160408-HK carbide turning insert is more than just a cutting tool—it is a productivity enhancer designed for high-performance machining of stainless steel, general steels, and alloys. With its triangular design, HK chip breaker, advanced coatings, and robust substrate, it delivers:

Longer tool life

Superior surface finish

Reliable chip control

Lower machining costs

Whether you are in automotive, aerospace, general machining, or energy sectors, the TNMG160408-HK insert ensures your production goals are met with precision, reliability, and efficiency.

By choosing our carbide inserts, you are investing in performance, innovation, and cost-effectiveness—backed by over three decades of carbide manufacturing expertise.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.