Product

SPMG-U type drill bit inserts

China Lizhou Hard Alloy Source Factory

Product Name:U Drilling inserts

Coating : PVD

Brand number:LMP208

Classification :

U Drill insert

keyword:

lizhou

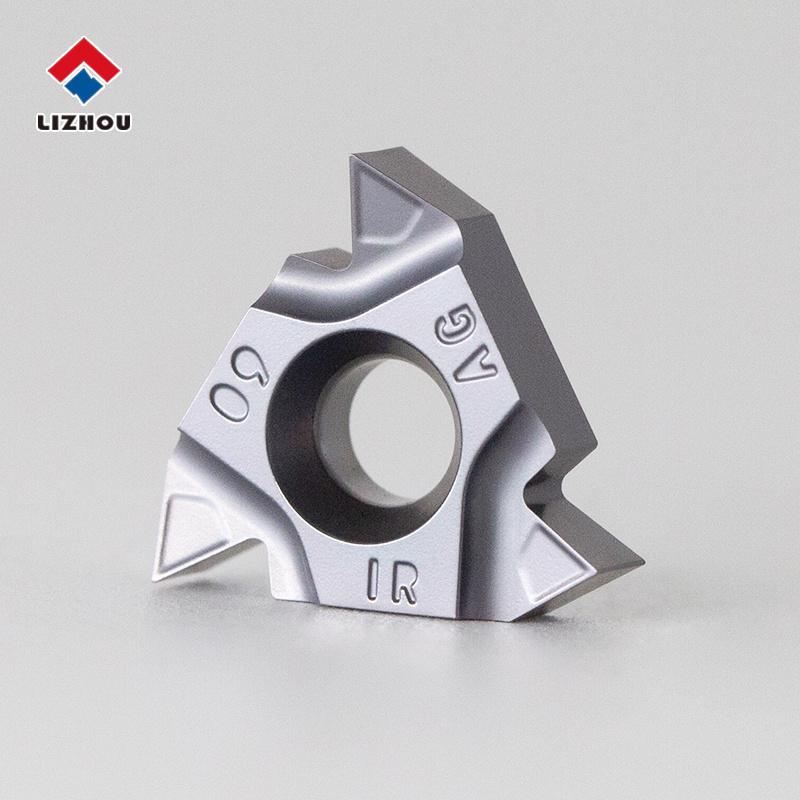

SPMG050204-DG U-Drill Insert: U type drill bit Inserts

1. Introduction: The Role of U-Drill Inserts in Modern Machining

Drilling is one of the most demanding operations in metalworking. Unlike turning or milling, drilling requires tools that can maintain accuracy and stability deep inside a workpiece, while also handling heat and chip evacuation effectively. This is why U-drills with indexable inserts have become the preferred solution across industries. They combine high material removal rates, cost efficiency, and adaptability.

At the heart of every U-drill lies the cutting insert—a small but critical component that determines performance, tool life, and machining quality. Lizhou Hard Alloy, with over 33 years of manufacturing experience, proudly introduces the SPMG050204-DG U-drill insert, engineered to deliver consistent drilling performance in diverse materials.

This article will analyze the advantages, designation meaning, parameters, applications, features, guidelines, and technical innovations of the SPMG050204-DG, ensuring users and buyers understand why it is a reliable choice for professional machining.

Type | Basic Dimensions (mm) | Machining Aperture ( mm ) | PVD | CVD | |||||

I.C | S | D | R | LPP208 | LMP208 | LKC208 | LPC208 | ||

SPMG050204-DG | 5.0 | 2.38 | 2.2 | 0.4 | 13.0-15.0 |

| √ |

|

|

SPMG060204-DG | 6.0 | 2.38 | 2.6 | 0.4 | 16.0-21.0 |

| √ |

|

|

SPMG07T308-DG | 7.94 | 3.97 | 2.8 | 0.8 | 22.0-27.0 |

| √ |

|

|

SPMG090408-DG | 9.8 | 4.3 | 4.1 | 0.8 | 28.0-33.0 |

| √ |

|

|

SPMG110408-DG | 11.5 | 4.76 | 4.4 | 0.8 | 34.0-42.0 |

| √ |

|

|

SPMG140512-DG | 14.3 | 5.2 | 5.5 | 0.8 | 43.0-50.0 |

| √ |

|

|

2. Decoding the Designation: SPMG050204-DG

Insert codes may appear complex, but each character provides essential details:

S → Insert shape. “S” typically refers to a square or modified geometry suitable for balanced drilling forces.

P → Tolerance and accuracy class, designed for precise insert interchangeability.

M → Relief angle and clearance, providing optimized cutting edge clearance to reduce friction.

G → Special chipbreaker or edge preparation suited for drilling.

05 → Insert size (edge length or inscribed circle, in millimeters).

02 → Thickness, indicating insert strength and heat dissipation capacity.

04 → Corner radius, which directly affects hole surface finish and insert durability.

DG → Lizhou-specific chipbreaker style and geometry, designed for smooth chip evacuation in drilling.

This designation ensures compatibility with a wide range of U-drill bodies, allowing machinists to select the right insert confidently.

3. Performance Advantages of SPMG050204-DG

a) Material Strength: Advanced Tungsten Carbide Composition

Produced from high-purity tungsten carbide powder with an optimized cobalt binder.

Fine-grain structure provides excellent hardness (above 90 HRA) while maintaining fracture toughness.

Enables reliable drilling in steels, cast iron, and stainless steel without premature edge failure.

b) Coating Technology for Extended Tool Life

Available with PVD or CVD multilayer coatings such as TiAlN or AlTiN.

Coatings reduce wear, oxidation, and built-up edge formation.

Improves performance in dry and wet machining environments.

c) Precision Geometry and Chipbreaker DG

The DG chipbreaker is engineered to handle chips efficiently, preventing clogging during deep hole drilling.

Reduces cutting resistance, lowering spindle load.

Provides smoother hole surfaces and minimizes burr formation.

d) Cost-Effective Drilling

Indexable design with multiple cutting edges per insert.

Reduced downtime thanks to quick insert indexing or replacement.

Higher productivity compared to solid carbide drills.

4. Applications Across Industries

The SPMG050204-DG U-drill insert is designed for versatility in industrial drilling operations:

Automotive Manufacturing

Drilling precise holes in engine blocks, crankshafts, and gear housings.

Handles mass production with consistency.

Aerospace Industry

Capable of drilling alloys such as titanium and Inconel.

Used in turbine components, wing structures, and landing gear parts.

Energy & Oilfield Equipment

Drilling in high-strength alloy steels and corrosion-resistant materials.

Reliable for heavy-duty operations in pipelines, valves, and casings.

General Machinery & Fabrication

Structural components, shafts, and flanges.

Flexible use in small workshops and large production lines alike.

5. Key Features and Benefits

Stable hole accuracy thanks to optimized geometry.

Excellent surface quality, reducing the need for reaming.

Multi-material compatibility: effective in steels, stainless steels, cast iron, and non-ferrous alloys.

Enhanced tool life with superior wear resistance.

Reduced machine load, improving spindle and holder longevity.

Quick change capability, minimizing downtime and increasing throughput.

6. Usage Guidelines and Precautions

To maximize insert performance and drilling efficiency, users should consider the following:

Cutting Speed: Choose speeds appropriate for the material (higher for cast iron, lower for hard alloys).

Feed Rate: Optimize feed to balance productivity and insert life.

Coolant: Ensure adequate coolant flow for heat removal and chip evacuation.

Machine Stability: Use rigid setups and avoid excessive tool overhang.

Insert Maintenance: Rotate or replace inserts at the recommended wear limit to maintain hole precision.

Precaution: Avoid pushing inserts beyond their wear threshold, as this risks damaging the U-drill body and compromising hole quality.

7. Technical Innovations and Lizhou’s Expertise

Lizhou Hard Alloy integrates continuous R&D into its insert production:

Patented chipbreaker profiles, such as DG, tailored for smooth drilling operations.

Nano-coating technology for extreme wear resistance.

Customized carbide substrates combining toughness with hot hardness.

Simulation-optimized edge geometries, ensuring minimal vibration and stable chip flow.

With over three decades of innovation, Lizhou has developed carbide solutions that compete with global brands while maintaining cost efficiency for international buyers.

8. Why Choose Lizhou Hard Alloy for U-Drill Inserts?

33 years of manufacturing expertise in tungsten carbide tooling.

Factory-direct supply, ensuring competitive prices and strict quality control.

Comprehensive product range, including turning inserts, milling inserts, and drilling inserts.

Global customer support, with technical guidance for cutting data and machining optimization.

Customization capability, offering OEM/ODM services for tailored tool solutions.

Conclusion

The SPMG050204-DG U-drill insert is a precision-engineered solution for modern drilling demands. With its fine-grain carbide structure, advanced coatings, and innovative DG chipbreaker, it delivers durability, efficiency, and consistent hole quality across a variety of materials.

By choosing Lizhou Hard Alloy, manufacturers gain access to not only high-performance inserts but also decades of technical knowledge, innovation, and reliable customer service. Whether in automotive, aerospace, oil & gas, or general engineering, the SPMG050204-DG provides the performance and cost-effectiveness that global buyers demand.

For businesses seeking stable drilling solutions and long-term cost savings, Lizhou’s U-drill inserts are the answer.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.