Product

WCMX\WCMT-U type drill bit blade

China Lizhou Hard Alloy Source Factory

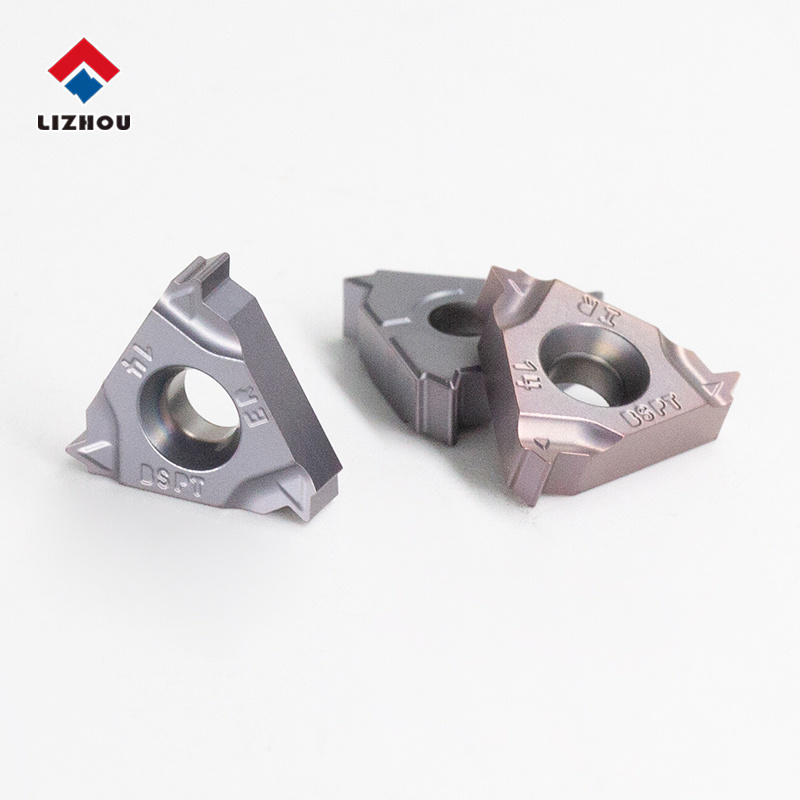

Product Name:U Drilling insert

Coating : PVD

Brand number:LMP208

Classification :

U Drill insert

keyword:

lizhou

WXMX040208A U-Drill Insert: High-Performance Tungsten Carbide Solution from Lizhou Hard Alloy

1. Introduction to Tungsten Carbide U-Drill Inserts

In modern machining, drilling operations are among the most critical processes in metalworking. High precision, tool durability, and efficiency are decisive factors that determine the quality and productivity of manufacturing. U-drills, also known as indexable insert drills, are widely used in industries such as automotive, aerospace, oil & gas, and heavy machinery. They rely on replaceable cutting inserts to optimize cost-effectiveness and performance.

The WXMX040208A U-Drill insert, produced by Lizhou Hard Alloy, represents a new generation of tungsten carbide cutting tools. With over 33 years of expertise in manufacturing high-performance carbide products, Lizhou has refined its insert design to deliver superior cutting ability, long tool life, and adaptability across different materials.

This article provides an in-depth analysis of the advantages, designation meaning, parameters, application fields, technical features, usage guidelines, and innovative aspects of the WXMX040208A U-drill insert.

Type | Basic dimensions (mm) | Machining aperture ( mm ) | PVD | CVD | |||||

I.C | S | D | R | LPP208 | LMP208 | LKC208 | LPC208 | ||

WCMX030208A | 5.56 | 2.38 | 2.8 | 0.8 | 16.0-20.0 | √ |

|

|

|

WCMX040208A | 6.35 | 2.38 | 2.8 | 0.8 | 21.0-25.0 | √ |

|

|

|

WCMX050308A | 7.94 | 3.18 | 3.2 | 0.8 | 26.0-30.0 | √ |

|

|

|

WCMX06T308A | 9.525 | 3.97 | 3.8 | 0.8 | 31.0-41.0 | √ |

|

|

|

WCMX080412A | 12.7 | 4.76 | 4.4 | 1.2 | 42.0-58.0 | √ |

|

|

|

Type | Basic dimensions (mm) | Machining aperture ( mm ) | PVD | CVD | |||||

I.C | S | D | R | LPP208 | LMP208 | LKC208 | LPC208 | ||

WCMT050308-FN | 7.94 | 3.18 | 3.2 | 0.8 | 26.0-30.0 |

| √ |

|

|

WCMT06T308-FN | 9.525 | 3.97 | 3.8 | 0.8 | 31.0-41.0 |

| √ |

|

|

WCMT0804012-FN | 12.7 | 4.76 | 4.4 | 1.2 | 42.0-58.0 |

| √ |

|

|

2. Product Designation Explained: WXMX040208A

The product code WXMX040208A may appear complex, but it follows ISO standard designation rules that define the insert’s geometry, size, and cutting characteristics.

W → Insert shape (often indicates a hexagonal or specialized design for drilling stability).

X → Relief angle and clearance type, designed to reduce friction and heat during drilling.

M → Tolerance class, ensuring high precision and interchangeability.

X → Chipbreaker or cutting edge style optimized for drilling.

04 → Insert size (edge length or inscribed circle dimension, typically in millimeters).

02 → Insert thickness, affecting strength and heat dissipation.

08 → Nose radius (in tenths of a millimeter), which determines surface finish quality.

A → Special cutting edge preparation, coating, or geometry unique to Lizhou’s design.

This detailed coding provides users with essential information at a glance, ensuring compatibility with different U-drill bodies and machining setups.

3. Performance Advantages of WXMX040208A U-Drill Insert

a) Material Advantage: Fine-Grain Tungsten Carbide

Manufactured from high-density tungsten carbide powder, with optimized cobalt binder composition.

Provides excellent hardness (>90 HRA) while maintaining toughness to resist chipping.

Enhanced wear resistance for extended tool life even under high-speed drilling conditions.

b) Advanced Coating Technology

Coated with PVD/CVD multilayer structures such as TiAlN, AlTiN, or TiCN.

Improves heat resistance, oxidation stability, and surface smoothness.

Ensures stable performance across various cutting speeds and coolant conditions.

c) Geometry and Chipbreaker Design

Special chip control grooves reduce cutting forces and ensure smooth chip evacuation.

Balanced cutting edge strength minimizes risk of insert breakage during deep hole drilling.

Reduces vibration and improves dimensional accuracy.

d) Cost Efficiency

Indexable insert design allows multiple cutting edges per insert.

Quick replacement reduces downtime compared to solid drills.

Optimized performance lowers per-hole cost.

4. Applications and Use Cases

The WXMX040208A U-drill insert is designed for high-performance drilling in a wide range of industries:

Automotive Industry

Cylinder block and head machining.

Precise drilling of engine and transmission components.

Aerospace Engineering

High-strength alloy drilling (titanium, Inconel, stainless steels).

Precision holes for structural parts and turbine components.

Oil & Gas Industry

Heavy-duty drilling in pipes, valves, and pressure vessels.

Consistent performance in alloy steels and corrosion-resistant materials.

General Engineering & Heavy Machinery

Structural parts, shafts, and flanges.

Suitable for mass production lines and custom machining workshops.

5. Key Features of WXMX040208A

High drilling stability thanks to optimized insert geometry.

Excellent surface finish, reducing the need for secondary reaming.

Multi-material versatility: works effectively on steels, cast iron, stainless steel, and non-ferrous alloys.

Reduced cutting forces, lowering spindle load and extending machine tool life.

Compatible with multiple U-drill bodies, ensuring broad interchangeability.

6. Usage Guidelines and Precautions

To maximize performance and tool life, users should follow recommended practices:

Cutting Speed: Adjust based on workpiece material. Higher speeds for cast iron, lower for tough alloys.

Feed Rate: Follow Lizhou’s cutting data charts to avoid overloading.

Coolant Supply: Ensure adequate coolant flow to remove chips and reduce heat.

Tool Holder Rigidity: Use stable toolholders and minimize overhang.

Insert Indexing: Replace or rotate inserts once edge wear reaches 0.2–0.3mm to maintain hole quality.

Precaution: Avoid reusing excessively worn inserts, as they can damage the U-drill body and compromise dimensional accuracy.

7. Technical Innovations and Patents

Lizhou Hard Alloy has invested in continuous R&D to enhance drilling insert performance:

Nano-structured coating layers for extended wear resistance.

Proprietary carbide substrate composition, combining ultra-fine WC grains with cobalt for balanced hardness-toughness ratio.

Optimized chipbreaker profiles, designed through simulation to minimize cutting resistance.

Patented edge preparation technology, ensuring sharp yet durable cutting edges.

These innovations ensure that the WXMX040208A U-drill insert remains competitive against leading international brands while offering cost-effective solutions for global buyers.

8. Why Choose Lizhou Hard Alloy?

With 33 years of carbide manufacturing expertise, Lizhou has become a trusted partner for industrial machining solutions. Our advantages include:

Factory-direct supply with strict quality control.

Global export experience, supplying to markets across Asia, Europe, Africa, and South America.

Custom solutions, including OEM/ODM services for special insert geometries and coatings.

Technical support, with engineers available to provide cutting parameter recommendations and troubleshooting.

Conclusion

The WXMX040208A U-drill insert is more than just a consumable cutting tool—it is a precision-engineered solution that enhances productivity, reduces machining costs, and ensures consistent drilling quality. With advanced carbide materials, innovative geometries, and coatings, this insert is tailored for demanding applications across industries.

By choosing Lizhou Hard Alloy, customers not only benefit from a high-performance product but also gain access to decades of expertise, reliable technical support, and a commitment to innovation.

If your business requires durable, precise, and cost-effective U-drill inserts, the WXMX040208A is the solution designed to exceed expectations.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.