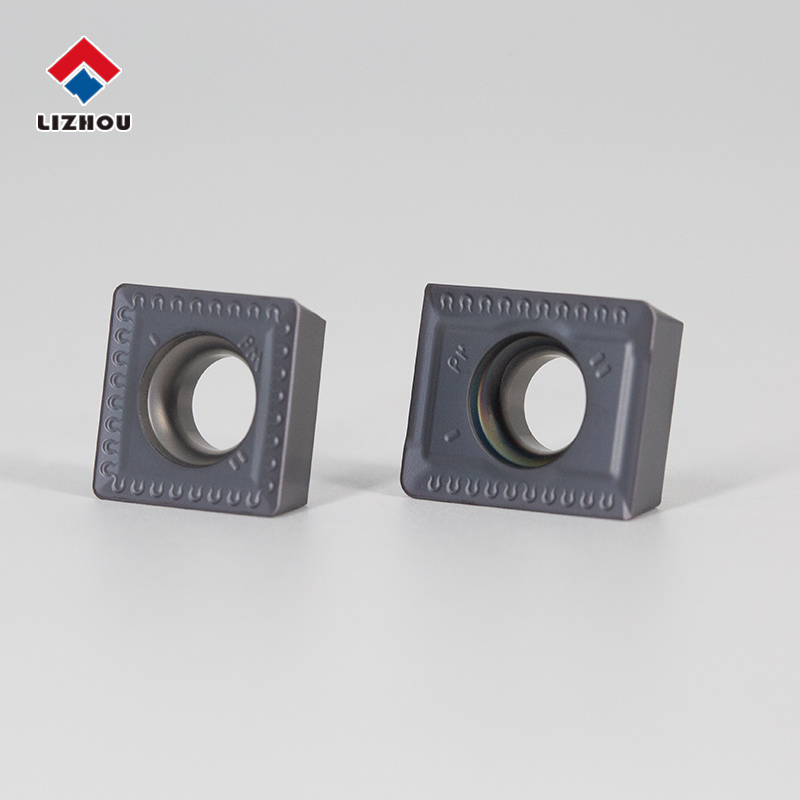

Product

TDC cut groove

China Lizhou Hard Alloy Source Factory

Model number:TDC3

Coating : CVD

Brand number:LMP203

Classification :

Grooving insert

keyword:

lizhou

TDC2 / TDC3 Carbide Cutoff and Grooving Inserts: Non-ferrous metals, steel, stainless steel, cast iron and difficult-to-machine materials

Introduction

In the field of modern metalworking, productivity and precision are no longer negotiable—they are essential. Manufacturers and machining centers require cutting tools that not only provide accuracy but also ensure efficiency, durability, and cost savings over long production runs. Among the wide range of cutting tool solutions, cutoff and grooving inserts hold a central role in parting, slotting, and shaping operations.

Our company, a trusted manufacturer of cemented carbide (hard alloy) products, is proud to present the TDC2 and TDC3 series carbide inserts, engineered specifically for cutoff and grooving operations. Built with advanced carbide technology, these inserts deliver outstanding wear resistance, exceptional toughness, and precise cutting results, making them a preferred choice in industries ranging from automotive to aerospace, and from general engineering to energy equipment production.

Type | Basic Dimensions (mm) | CVD | PVD | ||||||

L | B | T | r | D | LMP203 | LSP203 | LPC203 | LKC203 | |

TDC2 | 20.0 | 2.0 | 3.95 | 0.20 | 1.7 | √ |

|

|

|

TDC3 | 20.0 | 3.0 | 4.12 | 0.20 | 2.4 | √ |

|

|

|

TDC4 | 20.0 | 4.0 | 4.14 | 0.30 | 3.0 | √ |

|

|

|

TDC5 | 25.0 | 5.0 | 4.16 | 0.30 | 4.0 | √ |

|

|

|

TDJ2 | 20.0 | 2.0 | 3.90 | 0.20 | 1.7 | √ |

|

|

|

TDJ3 | 20.0 | 3.0 | 4.05 | 0.20 | 2.4 | √ |

|

|

|

TDJ4 | 20.0 | 4.0 | 4.05 | 0.30 | 3.0 | √ |

|

|

|

TDT3 | 20.0 | 3.0 | 4.00 | 0.40 | 2.2 | √ |

|

|

|

TDT4 | 20.0 | 4.0 | 4.02 | 0.40 | 3.0 | √ |

|

|

|

Understanding the TDC Series

The designation “TDC” reflects the insert’s classification within cutoff (T) and grooving (D) carbide (C) systems. Each element in the code provides useful information:

T → Tooling for cutoff (parting) operations.

D → Designed for slotting and grooving, offering versatile chip control.

C → Carbide material, ensuring hardness, wear resistance, and high cutting efficiency.

The numerical values following the letters (such as 2 and 3) represent the width specifications of the insert:

TDC2 → 2.0 mm insert width, ideal for narrow cuts and fine grooving.

TDC3 → 3.0 mm insert width, suited for medium to heavy parting tasks.

This clear coding system makes it easy for machinists to identify the right tool for specific parting or slotting operations, saving time and reducing tooling mistakes.

Advantages of Carbide Inserts in Cutoff and Grooving

Compared to traditional high-speed steel (HSS) tools, cemented carbide inserts such as TDC2 and TDC3 offer significant advantages:

Superior Hardness and Wear Resistance

Carbide inserts maintain cutting edge sharpness even at high temperatures, ensuring longer tool life.

Excellent Heat Resistance

Unlike HSS, carbide maintains structural integrity at higher cutting speeds, making it ideal for modern CNC machining.

Higher Cutting Speeds and Productivity

Reduced cycle time and increased output, critical for large-volume production.

Consistency and Accuracy

Achieve uniform part dimensions even over extended runs, reducing scrap rates.

Cost-Effectiveness

Though initial cost is higher, the long service life and fewer tool changes result in lower cost per part.

Surface Finish Quality

Produces smoother surface finishes, reducing the need for secondary finishing operations.

TDC2 and TDC3 – Features and Benefits

1. TDC2 – Precision in Narrow Cuts

Width: 2.0 mm

Application: Fine slotting, narrow cutoff operations, and delicate part separation.

Strengths:

Minimal material waste due to thin cutting width.

Reduced cutting forces, making it suitable for small-diameter parts.

High chip evacuation performance, minimizing risk of tool breakage.

2. TDC3 – Strength for Medium to Heavy Duty

Width: 3.0 mm

Application: Heavy-duty parting of larger workpieces, general grooving in automotive shafts, bearing rings, and pipe cutting.

Strengths:

Robust edge geometry for stable cutting under high load.

Improved rigidity, allowing deeper cuts without vibration.

Reliable chip control with specially designed groove geometry.

Usage Scenarios

Automotive Industry

Cutting of transmission shafts, axles, and steering components.

Precision grooving for sealing rings and snap-fit features.

Aerospace Manufacturing

Parting of high-strength alloys like titanium and Inconel.

Slotting components where accuracy is mission-critical.

General Engineering

Cutting and slotting in machine components, pumps, valves, and industrial machinery.

Energy Equipment

Tube cutting for oil & gas applications.

Parting operations on turbine and generator shafts.

Mass Production CNC Workshops

High-volume production lines requiring stable, long-life inserts.

Technical Features

Advanced Grain Structure: Our proprietary sintering process ensures uniform carbide grain size, resulting in balanced hardness and toughness.

Special Coating Technology: PVD/CVD coatings (TiAlN, AlTiN, or customized) enhance resistance to oxidation, abrasion, and built-up edge formation.

Optimized Chipbreaker Design: Dedicated cutting edge geometry ensures smooth chip flow, minimizing heat accumulation.

High Precision Ground Edges: Provides consistent tolerance and exact fit in insert seats.

Patented Geometry (optional): Our R&D team integrates innovative cutting-edge profiles that extend life while reducing cutting forces.

Precautions and Best Practices

Select the Right Width

TDC2 for light-duty precision cuts.

TDC3 for medium-duty, wider slotting.

Match Workpiece Material

Use appropriate coating grades for steel, stainless steel, cast iron, or superalloys.

Maintain Correct Cutting Parameters

Avoid excessive feed rates to prevent tool chipping.

Use recommended surface speed to maximize insert life.

Ensure Proper Cooling

Apply coolant directly to the cutting zone for improved chip evacuation and heat control.

Secure Toolholder Setup

Vibration reduces tool life; ensure proper clamping and machine rigidity.

Technical and Patent Innovations

Our company continuously invests in research and development to enhance the performance of carbide inserts. Some of the innovations in the TDC2 and TDC3 range include:

Reinforced Edge Stability: Special microgeometry design reduces the chance of edge chipping during interrupted cuts.

Low-Friction Coating Layers: Customized multilayer coatings reduce friction, allowing higher speeds and lower heat.

Advanced Powder Metallurgy: Ensures fine carbide particle distribution, improving resistance to cracking.

Chip Control Enhancements: Patented groove patterns guide chips away from the cutting zone, avoiding entanglement.

Why Choose Our TDC2 / TDC3 Inserts?

Proven Expertise – As a specialized hard alloy manufacturer, we control the full process from powder preparation to final inspection.

Tailored Solutions – Available in different coatings, edge preps, and chipbreaker designs.

Global Standards – Our inserts meet ISO standards for interchangeability and reliability.

Innovation-Oriented – Continuous improvement in design and materials.

Customer Support – Technical team assists in selecting proper grades, parameters, and troubleshooting.

Conclusion

The TDC2 and TDC3 carbide cutoff and grooving inserts represent the synergy of advanced hard alloy technology, precise engineering, and innovative design. Whether used for narrow, delicate parting or for heavy-duty grooving, these inserts deliver the durability, stability, and accuracy demanded by modern machining.

By choosing TDC2 or TDC3, manufacturers benefit from:

Longer tool life

Reduced downtime

Improved part quality

Lower cost per component

In a competitive global manufacturing landscape, our carbide inserts help companies achieve superior productivity and maintain their competitive edge.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.