Product

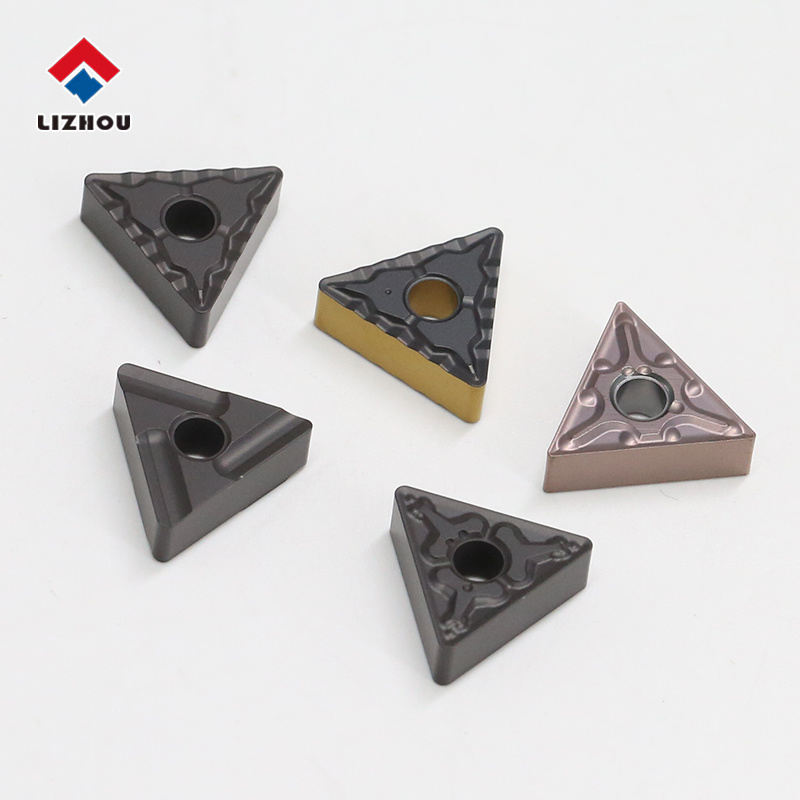

TNMG-TSF\TM Steel Turning Insert

China Lizhou Hard Alloy Source Factory

Product Name:Steel Turning Inserts

Coating : CVD

Brand number:LPC102\202

Classification :

Turning insert

keyword:

lizhou

TNMG-TSF/TM Carbide Turning Insert – Complete Product Guide

Introduction

As one of the leading carbide manufacturers, LIZHOU Carbide is committed to providing innovative cutting solutions for global industries. Among our wide portfolio of turning inserts, the TNMG-TSF/TM carbide insert is a versatile and high-performance option that delivers both durability and machining precision. This in-depth guide explains the technical background, advantages, parameters, applications, and innovations behind the TNMG-TSF/TM insert.

TYPE | Basic size(mm) | Cutting data | CVD | ||||||

I.C | S | D | R | Depth of cut(mm) | Feed(mm/tooth) | LPC102 | LPC202 | LPC302 | |

TNMG160404-TM | 9.525 | 4.76 | 3.81 | 0.4 | 1.20-5.00 | 0.15-0.50 |

| ⚪ |

|

TNMG160408-TM | 9.525 | 4.76 | 3.81 | 0.8 | 1.20-5.00 | 0.15-0.50 |

| ⚪ |

|

TNMG160404-TM | 9.525 | 4.76 | 3.81 | 1.2 | 1.20-5.00 | 0.15-0.50 |

| ⚪ |

|

TNMG160408-TSF | 9.525 | 4.76 | 3.81 | 0.4 | 0.20-1.80 | 0.08-0.40 | ⚪ |

|

|

TNMG160412-TSF | 9.525 | 4.76 | 3.81 | 0.8 | 0.20-1.80 | 0.08-0.40 | ⚪ |

|

|

TNMG160412-TSF | 9.525 | 4.76 | 3.81 | 1.2 | 0.20-1.80 | 0.08-0.40 | ⚪ |

|

|

1. Why Choose Carbide Inserts?

Carbide inserts dominate modern machining because they combine toughness with hardness. Unlike traditional high-speed steel tools, carbide inserts provide:

High cutting speeds, enabling greater productivity.

Longer service life, even under elevated temperatures.

Reduced tool change time, since inserts can be quickly indexed.

Consistent surface quality, crucial for precision engineering.

Lower total cost, thanks to multiple usable cutting edges.

The TNMG-TSF/TM builds upon these advantages with chipbreaker designs tailored for different machining needs.

2. Decoding the TNMG-TSF/TM Designation

Each letter and suffix in the insert name has a technical meaning:

T – Triangular insert, offering 6 cutting edges.

N – Relief angle 0°, which strengthens the cutting edge.

M – Tolerance class “Medium,” suitable for general turning.

G – Insert with hole, double-sided, indexable.

TSF – Chipbreaker designed for light to medium finishing, ensuring excellent chip control and surface finish.

TM – Chipbreaker optimized for medium machining, balancing chip evacuation and edge stability.

By reading this designation, machinists can select the correct insert according to material and cutting conditions.

3. Specifications and Parameters

The TNMG-TSF/TM insert is manufactured under strict ISO and ANSI standards. Key technical parameters include:

Insert size (IC): 16 mm (typical, depending on variant)

Thickness: 4.76 mm

Hole diameter: 3.81 mm

Relief angle: 0°

Cutting edges: 6

Nose radius: Available in 0.4, 0.8, and 1.2 mm options

Grades available: Coated and uncoated carbide grades for steel, stainless steel, and cast iron

Coating types: CVD coatings (TiCN, Al₂O₃, TiN) for wear resistance; PVD coatings (TiAlN, TiCN) for high toughness applications

These specifications allow the TNMG-TSF/TM to adapt to varied cutting environments.

4. Application Fields

The TNMG-TSF/TM carbide insert is engineered for a wide range of turning applications. Typical usage scenarios include:

Automotive industry: shafts, gears, engine housings

General engineering: steel pipes, flanges, machine components

Energy sector: turbine components, large-diameter steel parts

Aerospace: precision parts requiring dimensional accuracy

Tool and mold making: semi-finishing and finishing tasks

TSF chipbreaker: Best suited for finishing steels and stainless steels, ensuring fine surface finish.

TM chipbreaker: Designed for medium cutting where chip evacuation and stability are equally important.

5. Distinct Advantages

The TNMG-TSF/TM offers several benefits that differentiate it from standard inserts:

Six usable cutting edges, reducing cost per component.

Triangular design, ensuring balanced cutting forces.

Tailored chipbreaker designs (TSF for finishing, TM for medium cutting).

Excellent wear resistance, supported by advanced coatings.

Stable edge strength, thanks to the 0° relief angle.

Wide material compatibility, covering steel, stainless steel, and cast iron.

These features make it a cost-effective yet high-performance solution.

6. Usage Guidelines and Precautions

For maximum performance, machinists should follow these best practices:

Select TSF geometry for finishing operations and TM geometry for medium cutting.

Adjust feed and speed based on workpiece hardness and toughness.

Use rigid clamping systems to minimize vibration.

Apply coolant when machining stainless steel to reduce heat buildup.

Rotate or replace the insert once flank wear exceeds recommended limits.

Following these recommendations ensures stable machining and extended tool life.

7. Technology and Innovation at LIZHOU

LIZHOU Carbide integrates advanced technologies into the TNMG-TSF/TM:

High-density carbide substrates offering toughness and hardness balance.

Nano-layer CVD/PVD coatings to resist wear and thermal shock.

Unique chipbreaker geometries, designed using finite element analysis.

Precision edge preparation, ensuring reduced cutting forces and improved finish.

Patented coating technology, prolonging insert lifespan under harsh conditions.

Through continuous innovation, we ensure that our products remain competitive and aligned with international quality standards.

TNMG160404-TM\43 FAQ

Q1: How to choose between TM and 43 models?

Both TM and 43 are suitable for processing steel materials, suitable for lathes, TM automotive shaft finishing and semi-finishing continuous processing,

Q2: What is the minimum order quantity (MOQ)?

Standard MOQ: 10 boxes (100 pieces), support sample orders (1 box minimum order).

Packaging and warranty commitment

Standard packaging: 10 pieces/box, support customization.

Logistics solution: global air/sea transportation, provide DDP to door service.

Conclusion

The TNMG-TSF/TM carbide turning insert is a reliable and versatile solution for industries requiring efficient turning operations. With its triangular geometry, six cutting edges, advanced coatings, and specialized chipbreakers, it provides excellent performance across finishing and medium machining tasks.

As a trusted carbide manufacturer, LIZHOU Carbide remains dedicated to delivering cutting tools that improve productivity, reduce costs, and meet the evolving demands of modern manufacturing. The TNMG-TSF/TM insert stands as a testament to this commitment, combining precision, durability, and innovation.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.