Product

VNMG-TSF\TM Steel Turning Insert

China Lizhou Hard Alloy Source Factory

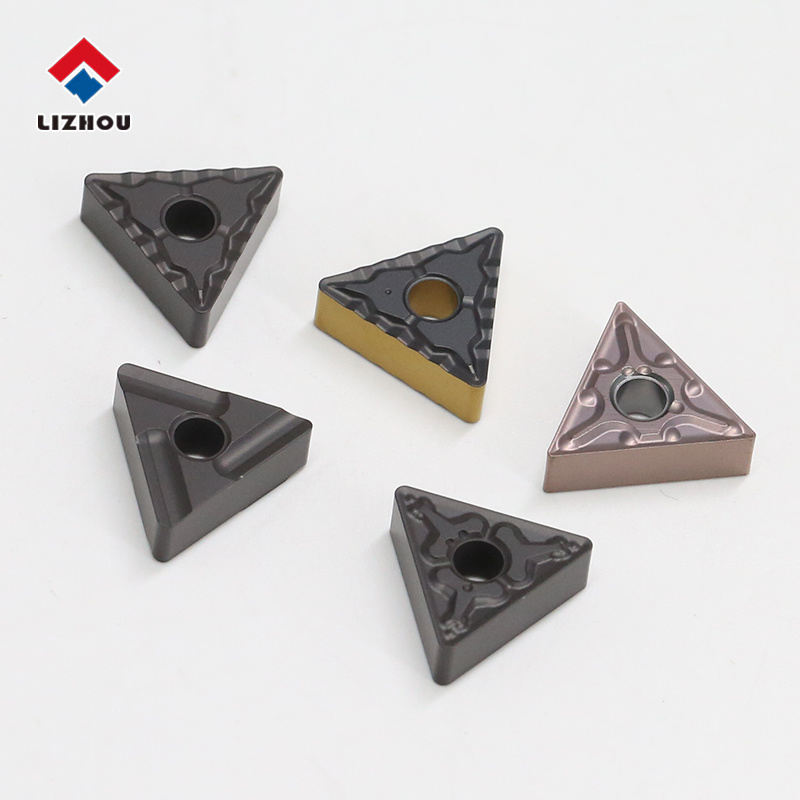

Product Name:Steel Turning Inserts

Coating : CVD

Brand number:LPC202

Classification :

Turning insert

keyword:

lizhou

VNMG-TSF/TM Steel Turning Insert – Complete Product Guide

Introduction

With more than 33 years of expertise in carbide manufacturing, LIZHOU Carbide delivers world-class cutting tool solutions for industries around the globe. Among our premium range of turning inserts, the VNMG-TSF/TM steel turning inserts stand out for their precision, durability, and adaptability in high-demand machining environments. This guide explores the technical details, performance advantages, application fields, and innovations behind the VNMG-TSF/TM inserts.

TYPE | Basic size(mm) | Cutting data | CVD | ||||||

I.C | S | D | R | Depth of cut(mm) | Feed(mm/tooth) | LPC102 | LPC202 | LPC102 | |

VNMG160404-TM | 9.525 | 4.76 | 3.81 | 0.4 | 0.80-3.00 | 0.15-0.35 |

| ⚪ |

|

VNMG160408-TM | 9.525 | 4.76 | 3.81 | 0.8 | 1.00-3.00 | 0.17-0.35 |

| ⚪ |

|

VNMG160408-TM | 9.525 | 4.76 | 3.81 | 1.2 | 1.20-3.00 | 0.19-0.35 |

| ⚪ |

|

VNMG160404-43 | 9.525 | 4.76 | 3.81 | 0.4 | 0.80-3.00 | 0.15-0.35 |

| ⚪ |

|

VNMG160408-43 | 9.525 | 4.76 | 3.81 | 0.8 | 1.00-3.00 | 0.17-0.35 |

| ⚪ |

|

VNMG160408-43 | 9.525 | 4.76 | 3.81 | 1.2 | 1.20-3.00 | 0.19-0.35 |

| ⚪ |

|

1. Why Carbide Inserts Are Essential in Modern Machining

Carbide inserts outperform traditional high-speed steel tools due to their ability to handle tough materials and sustain higher cutting speeds. The VNMG-TSF/TM series exemplifies the following key benefits:

High cutting efficiency – reduces machining time without compromising quality.

Superior heat resistance – stable performance even under high temperatures.

Extended tool life – fewer insert changes mean reduced downtime.

Excellent surface finish – crucial for precision steel components.

Optimized cost efficiency – multiple cutting edges per insert lower the overall cost per part.

These advantages make carbide inserts the industry standard for steel turning.

2. Understanding the VNMG-TSF/TM Designation

Each character in the VNMG code reflects specific insert features:

V – Rhombic insert with 35° angle, ideal for profiling and finishing.

N – Relief angle of 0°, maximizing edge strength.

M – Medium tolerance class, providing balance between accuracy and versatility.

G – Double-sided insert with hole for secure clamping.

TSF – Chipbreaker geometry designed for fine to medium finishing with superior chip control.

TM – Chipbreaker geometry for medium cutting, ensuring excellent stability and chip evacuation.

This designation system helps machinists quickly identify the correct insert for specific operations.

3. Key Specifications and Parameters

The VNMG-TSF/TM turning inserts conform to ISO standards and are available in multiple variations. Common parameters include:

Insert shape: 35° rhombic

Insert size (IC): 16 mm (typical, depending on type)

Thickness: 4.76 mm

Hole diameter: 3.81 mm

Relief angle: 0°

Cutting edges: 4 per insert

Nose radius options: 0.2 mm, 0.4 mm, 0.8 mm, and 1.2 mm

Grades available: Coated and uncoated carbide grades for steel and stainless steel

Coating options:

CVD coatings (TiCN, Al₂O₃, TiN) for superior wear resistance

PVD coatings (TiAlN, TiCN) for high-toughness operations

These variations allow machinists to select the most suitable insert based on cutting conditions.

4. Application Scenarios

The VNMG-TSF/TM inserts are widely used across industries that demand precision and efficiency in steel machining:

Automotive – crankshafts, engine parts, transmission housings

Aerospace – structural steel components requiring tight tolerances

Oil and gas – pipes, valves, and heavy-duty steel equipment

General engineering – shafts, flanges, and fittings

Tool and die manufacturing – semi-finishing and finishing of precision molds

TSF Geometry: Best for light finishing operations on steel and stainless steel, ensuring smooth surfaces and controlled chip evacuation.

TM Geometry: Tailored for medium cutting operations, balancing chip control with robustness in interrupted cuts.

5. Advantages of VNMG-TSF/TM Inserts

The VNMG series provides distinct performance advantages:

Four effective cutting edges, extending tool life and reducing costs.

Slim 35° design, excellent for profiling and fine detail work.

Specialized chipbreakers – TSF for finishing, TM for medium operations.

Coating versatility, ensuring optimal wear resistance and heat stability.

Reliable clamping system, minimizing vibration during machining.

Superior surface finish, even on difficult-to-machine steels.

These qualities make the VNMG inserts a preferred choice in precision steel turning.

VNMG160404-TM FAQ:

Q1: What materials are suitable for VNMG blades?

Core advantage materials: stainless steel (304/316), alloy steel (42CrMo/40Cr), titanium alloy

Not recommended materials: hardened steel (HRC>50), cast iron

Q2: What is the minimum order quantity (MOQ)?

Standard MOQ: 10 boxes (100 pieces), sample orders (1 box minimum order) are supported.

Packaging and warranty commitment

Standard packaging: 10 pieces/box, customization is supported.

Logistics solution: global air/sea transportation, DDP to door service is provided.

6. Usage Recommendations and Precautions

To maximize the performance and lifespan of VNMG-TSF/TM inserts, consider the following guidelines:

Select TSF chipbreaker for finishing and TM chipbreaker for medium cutting.

Use rigid and stable tool holders to avoid vibration.

Apply cutting fluid when machining stainless steel to reduce heat and improve tool life.

Monitor wear patterns and index the insert before excessive flank wear develops.

Avoid improper clamping torque that could compromise insert stability.

Following these recommendations ensures consistent results and prolonged insert service.

7. LIZHOU’s Technological Innovation

As a carbide manufacturer, LIZHOU integrates research-driven innovation into every VNMG insert:

Micro-grain carbide substrates for toughness and hardness balance.

Advanced nano-layer coatings to withstand extreme cutting temperatures.

Precision chipbreaker designs, developed using computer simulations.

Edge preparation technology, lowering cutting resistance while improving tool stability.

Proprietary coating processes, increasing tool life under high-speed operations.

Through these technologies, LIZHOU Carbide ensures that the VNMG-TSF/TM inserts remain globally competitive and aligned with the evolving needs of modern steel machining.

Conclusion

The VNMG-TSF/TM steel turning inserts are designed to provide machinists with precision, durability, and flexibility in steel cutting operations. Featuring a slim rhombic profile, multiple cutting edges, and advanced chipbreaker geometries, these inserts excel in both finishing and medium machining tasks.

As a trusted carbide manufacturer, LIZHOU Carbide is committed to supplying world-class turning solutions that improve productivity, reduce costs, and deliver superior machining performance. The VNMG-TSF/TM series is a testament to this commitment—engineered for excellence in steel turning.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.