Blog

Carbide lathe tool

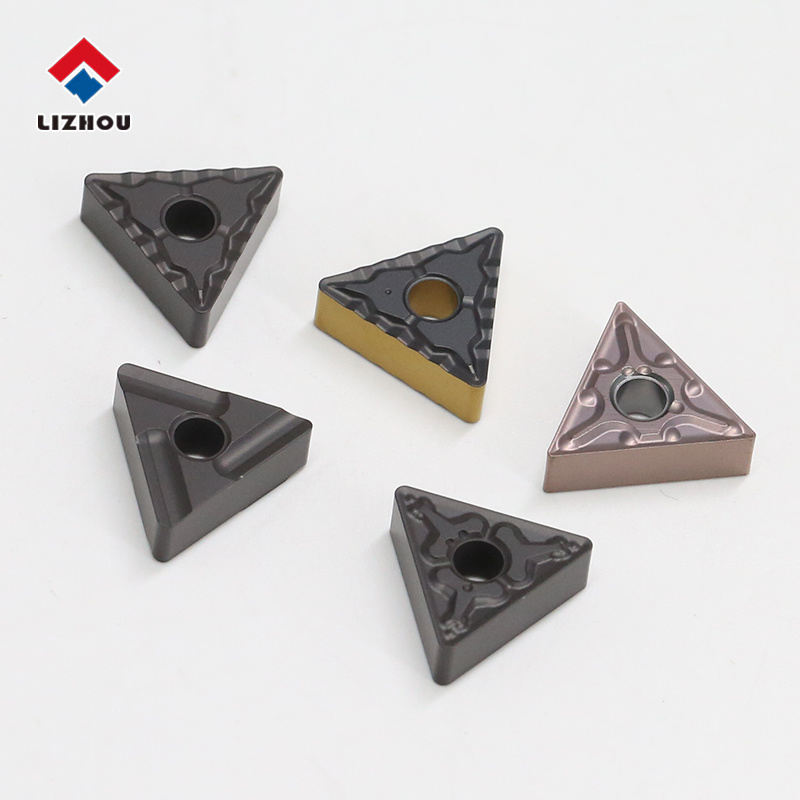

In the field of machining, Carbide tool tips Lathe tools ( Carbide Tipped Lathe Tools ) 、 Carbide tools ( Carbide Cutters ) and Carbide tipped turning tools ( Carbide Tip Turning Tools ) due to their excellent wear resistance, high temperature resistance, and long lifespan, have become the preferred sharp tools for modern precision machining.

I. Why choose carbide tools?

The hardness of cemented carbide (tungsten carbide-based composite material) can reach HRA 90 or more, which is that of high-speed steel by 2-3 times, and can maintain performance at 800-1000℃ high temperatures. This means:

Improved processing efficiency : Supports higher cutting speeds

Significantly reduced costs : Extended blade life 3-5 times

Stable processing quality : Reduces tool change downtime

II. Carbide Tools ( carbide cutters ) Applicable Material List

Stainless steel series ( 304/316/420 etc.)

Alloy steel and tool steel ( 45# steel, H13 mold steel, etc.)

Cast iron (gray cast iron, ductile cast iron)

III. What technical support does Lizhou provide?

For different material properties, we provide the following technical guarantees:

- Free sample service: provides 5 heavy-duty insert suitable for cutting

- Cutting parameter database: automatically generates processing solutions by entering material grades

- Customized coatings: optimize coating composition for special materials.

Each material provided by Zhuzhou Lizhou Carbide Cutting Tools Company details its usage scenarios and advantages. At the same time, the advantages of cemented carbide are emphasized, such as wear resistance, high temperature resistance, and suitability for high-strength machining.

Recommended products