Product

We specialize in the production of aluminum machining end mills. Our products utilize high-performance cemented carbide substrates and specialized cutting edge geometries, widely applied in aerospace, automotive, and mold industries. Products feature high surface finish, high chip removal rate, and high-speed adaptability, making them an ideal choice for CNC machining of aluminum alloys.

The four-flute end mill is made of high-hardness tungsten steel, which is sturdy and durable, using imported ultra-fine particle tungsten steel raw material, providing higher wear resistance and strength.

Thethree-flute end mill is made of high-hardness tungsten steel, which is sturdy and durable, using imported ultra-fine particle tungsten steel raw material, providing higher wear resistance and strength.

In modern machining, the demand for precision, speed, and durability continues to grow across industries such as aerospace, mold manufacturing, automotive, energy, and general engineering. Among the wide range of cutting tools available, carbide end mills have emerged as the standard for high-performance milling operations.

Widely used for slot machining, side machining, and step surface machining, it can also perform drilling and milling operations. However, the fewer the cutting edges, the better the effect.

Widely used for slot machining, side machining, and step surface machining, it can also perform drilling and milling operations. However, the fewer the cutting edges, the better the effect.

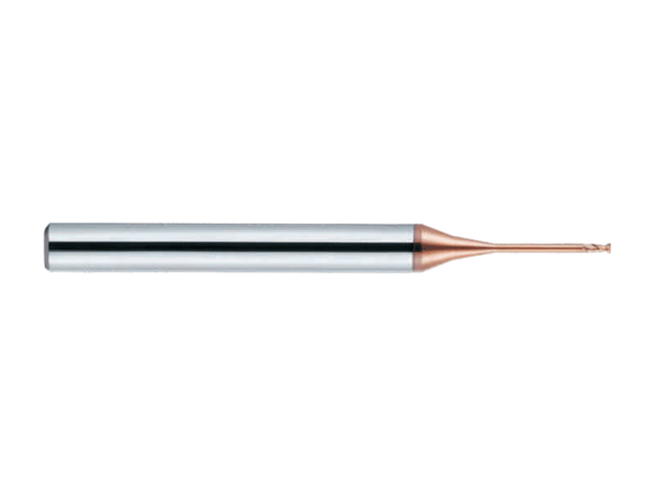

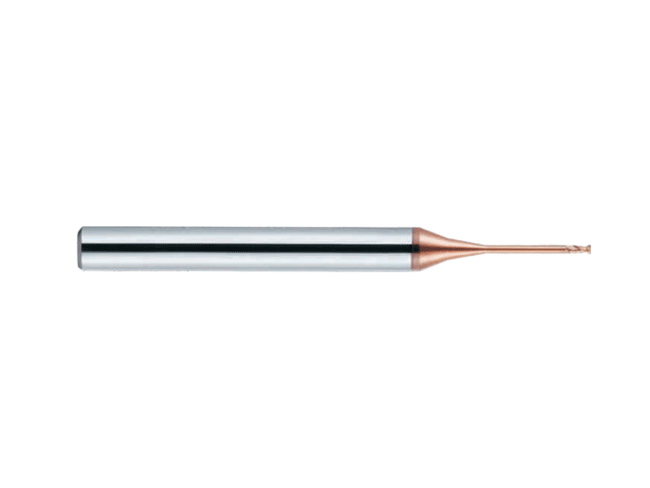

The flat cutting edge of the two-flute ball end mill provides precise and sharp cutting, resulting in a smooth workpiece surface and accurate dimensions.

The tool shapes and applicable processing scenarios of the two are different: the two-blade deep groove ball nose end mill is similar to a regular end mill, but the chip removal groove design of the two-blade deep groove ball nose end mill is deeper.