Blog

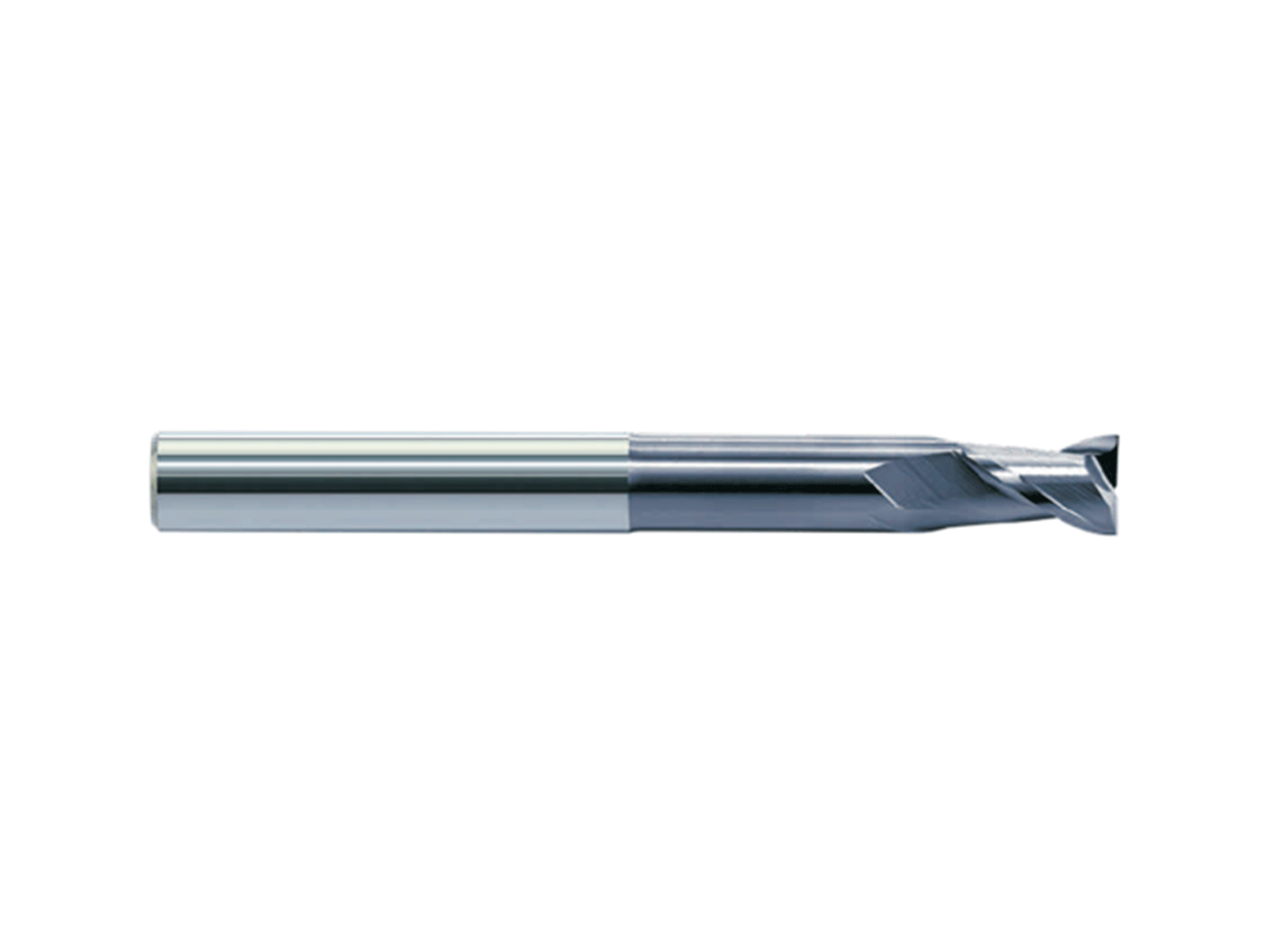

HRC60 Surface Machining Tungsten Steel 4-Flute Ball-Nose End Mill

In mold machining, precision part machining, and 3D surface machining, arc-end mills are indispensable tools. Whether it’s complex cavities, R Whether it’s rounded arc transitions or 3D surface profiling cutting with high-hardness steel, a stable and durable arc cutter can significantly enhance both efficiency and workpiece quality.

This time, Lizhou introduces... 60 Tungsten steel grade 4 End mill with rounded cutting edge Made from LiZhou’s proprietary high-end cemented carbide rods, these products feature high toughness, excellent wear resistance, and outstanding stability, making them particularly well-suited for machining ≤ HRC60 Quenched steel, tool steel, and martensitic stainless steel are powerful allies for mold factories and machining workshops.

I. Specifically for HRC60 Designed with high-hardness materials, offering higher strength and longer service life.

When machining high-hardness materials such as quenched steel and tool steel, conventional round-corner cutting tools tend to suffer from rapid wear, chipping, and unstable machining dimensions. 60 The tungsten steel ball-nose end mill features a high-strength, highly stable carbide substrate, ensuring that the tool maintains excellent sharpness even under heavy loads or during prolonged cutting operations.

Applicable materials include:

≤ HRC60 quenched steel

Tool steel (such as SKD11、D2、Cr12 Wait)

Martensitic stainless steel

High-hardness mold cavity material

It's a "hard steel arc blade" that is highly frequently searched by customers. HRC60 arc Common models of end mills and quenched steel end mills.

2. The four-edge arc-head design is specifically engineered for highly efficient and stable cutting.

Compared to two-blade arc-end mills, four-blade arc-end milling cutters have distinct advantages when machining hard materials:

The tool has greater rigidity.

Less vibration

Higher surface finish

Cutting is smoother and less likely to produce tool marks.

The arc-head structure itself is well-suited for machining curved surfaces, while the four-flute design further enhances machining efficiency, enabling the tool to remove material rapidly during curved-surface machining and achieve superior surface quality during the semi-finishing stage.

Also commonly referred to by users as “four-edge arc cutter, stable arc milling cutter, high-gloss arc cutter.”

Three, You Groove + Double-edged flute design ensures smooth chip removal and more stable machining.

Cutting hard materials generates large chip volumes and high temperatures. If chip removal is not smooth, it can easily lead to overheating of the tool, accelerated wear on the cutting edge, and even chipping of the blade.

60 The arc milling cutter uses:

✔ You Chip-removal groove (large-space chip flow)

Higher chip removal efficiency, preventing chip clogging when machining deep grooves and cavities.

✔ Double-edged belt structure (for more stable guidance)

Improve the dimensional consistency of tool side-wall machining and make the toolpath smoother.

This design ensures stable tool performance during high-speed machining as well as 3-axis or 4-axis contouring, making it one of the best choices for mold-making users who are looking for “arc-shaped cutters with excellent chip evacuation and stable arc milling cutters.”

4. Arc-shaped structure, specially designed for R Corner, circular groove, and contour machining design

The greatest advantage of arc knives is that they can machine various three-dimensional curved surfaces and arc-shaped structures, including:

R Corner processing

Round groove machining

Cavity Surface Machining

Contour machining with profiling

Round corner transition of the flow channel

Mold cavity chamfer / Arc Connection

The ball-end shape allows the tool to make contact with the workpiece at various angles, enabling smooth transitions without leaving noticeable tool marks—making it particularly well-suited for mold products and parts with complex curved surfaces.

5. Complete range of specifications, supports non-standard customization.

To accommodate different machine tools and workpieces with varying structures, Lizhou Tools offers:

Complete standard specifications (diameter / Blade length / Handle length)

Neck lengthening, S Neck type and long-blade type are customizable.

Special R Values and special coatings are customizable.

OEM/ODM Batch service

Meet the needs of equipment such as precision engraving machines, machining centers, and milling engraving machines.

Six: Why Choose Lizhou? 60 degree 4 blade Arc End mill?

From a practical machining perspective, the value this tool can bring includes:

1 — Hard materials are resistant to chipping and blade wear, offering greater stability.

2 Chip removal is smooth, and even when machining deep cavities, chips do not accumulate.

3 • High surface finish, reducing the need for subsequent polishing.

4 Surface finishing is smoother, with fewer tool marks.

5 — Stable lifespan and lower overall processing costs.

6 Our self-developed bar stock boasts stable quality and enhanced seismic resistance.

7 Wide range of applications; commonly stocked models for workshops.

For companies that need to machine mold steels, curved surfaces, and cavity structures, this is a highly reliable ball-nose end mill.

Recommended products