Blog

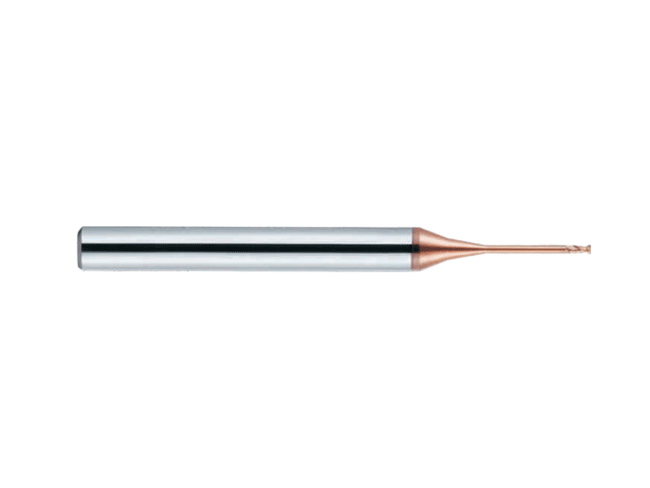

Tungsten Steel 65° 2-Flute Ball-Nose End Mill | Rough Machining of HRC65 Quenched Steel

In mold manufacturing, precision part machining, and heavy-duty cutting, when facing... HRC65 For high-hardness materials such as quenched steel, tool steel, and martensitic stainless steel, the selection of cutting tools is particularly critical. During the rough machining stage, large chip volumes and high cutting resistance can easily lead to issues like chipping, tool breakage, and aggravated tool marks if the cutting tools fail to evacuate chips effectively or lack sufficient strength, directly impacting machining efficiency and product quality.

Today, Lizhou is bringing you this tungsten steel product. 65 degree 2 End-mill cutter with blade head It is specifically designed for rough machining of high-hardness materials and for machining complex curved surfaces. It features excellent chip evacuation capability, sharp cutting edges, and a hemispherical tip that is suitable for a wide variety of applications. 3D The ball-end mill for machining high-hardness steel is a standard tool commonly stocked in mold factories and CNC machining workshops.

I. Applicable to ≤ HRC65 High-hardness material with stable and reliable performance.

Many customers process quenched steel or HRC65 When it comes to tool steel, the biggest concern is tool life. Ordinary tools find it difficult to withstand prolonged cutting on this material, but this one... 2 The blade-head cutter is made from high-strength tungsten steel bars and is specially designed for machining high-hardness steels:

Applicable to HRC60 – HRC65 Quenched steel

Suitable for tool steel, D2、 SKD11 High-hardness mold steel

Machinable Martensitic Stainless Steel

Suitable for rough machining of cavities, 3D Roughing of curved surfaces

It meets the frequently searched keyword needs of customers:

“ HRC65 Ball-end mills, quenched steel ball-end mills, ball-end mills for hard steel machining, ball-end mills for mold steels, and wear-resistant ball-end end mills.

For machining centers, milling machines, and high-speed machines, this tool maintains stability, durability, and minimal chipping even when working with high-hardness materials, making it one of the key tools for improving workshop efficiency.

2. Two-flute design—ensures powerful chip removal, high efficiency, and is truly ideal for rough machining.

The two most important points for rough machining:

Chip removal is smooth. + High metal removal rate ( MRR ).

And 2 Blade-head knives have a natural advantage in this regard:

✔ Larger chip flutes

The two-edge structure makes the groove wider, allowing chips to be easily curled and discharged without accumulating or clogging the groove.

✔ Chip removal is smoother

Chip removal is smooth. = Reduce cutting heat = The tool has a longer lifespan.

✔ Higher metal removal rate

It can handle greater cutting depths and feeds, making it suitable for heavy-duty rough machining.

Therefore, it is particularly suitable for:

Roughing the mold cavity

Rough machining of deep cavities and deep grooves

3D Large-area rough machining of curved surfaces

Deep and heavy cutting of quenched steel

3. Hemisphere blade tip structure, specially designed for complex curved surfaces.

The cutting edge of a ball-nose end mill is a standard hemispherical shape, making it more versatile than a flat-end mill.

Capable of machining various curved surfaces and 3D shapes.

Perfect for the inside of workpieces. R Corner and arc transition

Flow channels, fillets, and free-form surfaces suitable for mold cavities

Suitable for contour machining, bevel machining, 3D Contour machining

The machined surface is smoother and the tool marks are softer—this is why “ball-end mills for curved surface machining” are favored in the mold-making industry. 3D Contouring ball-end mill, R Corner kick head blade.

For machining shops that frequently process curved parts, this ball-end mill can effectively reduce subsequent polishing time and improve overall efficiency.

4. Lizhou Cutting Tools—Comprehensive Process Control from Materials to Manufacturing Processes

The stability of a cutting tool stems not only from its materials but also from each and every manufacturing process. Lizhou uses high-quality bar stock developed and produced in-house, and through five-axis grinding, precise edge treatment, and multiple rigorous inspections, ensures that the tools deliver consistent performance and predictable service life in actual machining applications.

Whether it’s heavy cutting, continuous long-time machining, or complex cavity milling, the tool maintains consistent performance, with little risk of chipping or premature failure.

5. Complete specifications, supporting non-standard customization.

To accommodate different machine tools, different structures, and different machining strategies, Lizhou provides:

Custom special blade length

Long-neck ball knife, extended-handle ball knife

Special R Corner

Special groove type

Special coating

OEM/ODM

Let the tools better match your actual machining processes, so you’re not constrained by standard tools.

Six: Why Customers Choose Lizhou 65 degree 2 End-mill cutter with a blade head?

In HRC65 Harder materials offer greater wear resistance and longer service life.

Rough machining chips are discharged smoothly without clogging.

The ball head is more suitable. R Angle and Surface Machining

The tool has good rigidity and is not prone to breakage.

High stability, strong processing consistency

Wide range of applications; commonly stocked in workshops.

Self-developed bar stock, more reliable.

Supports customization to meet complex operating conditions.

It’s a ball-nose end mill that truly addresses the pain points of “hard steel being difficult to machine, low efficiency in rough machining, and tool chipping easily.”

Recommended products