Blog

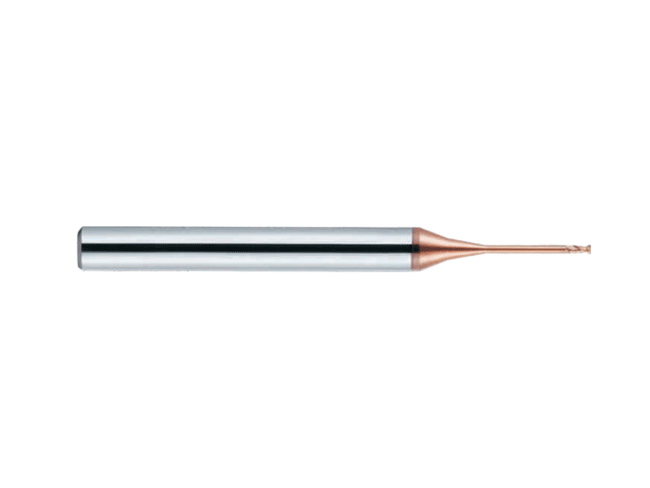

HRC60 High-Hardness Material Tungsten Steel 2-Flute Ball-Nose End Mill

In CNC machining, when dealing with high-hardness materials such as quenched steel, tool steel, and martensitic stainless steel, maintaining stable tool life while ensuring efficiency has always been a key concern in the workshop. Whether the cutting edge of the tool is sharp, chip removal is smooth, and surface finishing on curved areas is stable all directly affect the final workpiece’s precision and machining cycle time.

Today, we’d like to introduce you to tungsten steel, which excels in the rough machining stage. 2 End-mill cutter with blade head This tool not only boasts excellent chip removal capability but is also suitable for machining complex curved surfaces. It is ideal for cutting mold steels and machining cavities. 3D The ideal choice for surface machining and roughing toolpaths.

I. Applicable to ≤ HRC60 High-hardness material, specially designed for "hard materials."

Ordinary cutting tools in machining HRC60 When using materials of the above-mentioned grades, problems such as rapid wear, significant vibration, and chipping of the cutting edge often arise. Tungsten steel 2 The blade-type end mill uses a high-strength cemented carbide substrate and is capable of machining the following materials:

≤ HRC60 Quenched steel \ Tool steel (such as Cr12、D2、SKD11 Wait) \ Martensitic stainless steel

Suitable for cavities in high-hardness materials, 3D Rough machining of 3D surfaces

Deep grooves, runners, and rounded corner transitions in mold structures.

For factories that routinely machine mold components, shaped surfaces, and precision cavities—whether they’re mold manufacturers, parts processing shops, or CNC subcontracting workshops—this tool offers reliable performance.

II. Why do we say “two”? 0 “Is the end-mill with a blade tip the king of rough machining?”

Compared to three-flute or four-flute tools, 2 The greatest advantage of blade-type milling cutters lies in their smooth chip removal. During rough machining, where cutting loads are high and chip volumes are large, inefficient chip removal can lead to: tool heating, chips jamming against the tool, resulting in chipping, burning on the machined surface, chip blockage in the flute, and ultimately, tool breakage.

2 The flute geometry of blade-type cutting tools is wider, providing greater chip evacuation space, thus enabling smooth cutting even under machining conditions characterized by high feed rates, deep cuts, and high metal removal rates.

The advantages include: larger chip evacuation space, less likelihood of chip clogging, evenly distributed machining load for lighter and smoother cutting, stable tool life, suitability for high-speed rough machining, and a significant improvement in machining efficiency.

3. Hemispherical blade tip structure, suitable for complex surfaces and 3D Processing

The biggest difference between a ball-nose end mill and a conventional flat-end mill is that the cutting edge of the ball-nose end mill is hemispherical. This gives it an inherent advantage when machining curved surfaces:

The blade tip is resistant to chipping.

The cutting path is smoother, ideal for intricate curves.

Capable of machining cavity bottoms, rounded corners in grooves, and streamlined structures.

More suitable 3D Mold surface, carved surface, inclined surface, freeform surface

The ball-end design allows the tool to cut along three-dimensional surfaces without leaving any dead spots, and prevents blade breakage caused by excessive load on sharp corners.

IV. Structural Advantages: Stability, Efficiency, and Strong Adaptability

1. High-toughness cemented carbide substrate

Enhance the tool's resistance to bending and reduce the risk of chipping.

2. Cutting is smoother and vibration is reduced.

2 The blade structure enables the tool to remain stable during high-speed machining and reduces the likelihood of tool marks.

3. Compatible with a variety of operating conditions

It delivers outstanding performance whether used for roughing, semi-finishing, or machining complex freeform surfaces.

4. Complete range of sizes and specifications, custom orders accepted.

Ball-nose end mills have a wide range of applications; simply select different diameters and cutting lengths based on the workpiece’s structure. R Angles can meet most machining requirements.

5. Why are workshops more inclined to use tungsten steel ball-end mills for roughing?

The biggest challenges in rough machining are: long machining time, large material removal rate, rapid tool wear, complex toolpaths, and high workpiece hardness.

Tungsten steel 2 The blade knife precisely addresses these core issues:

✔ Higher metal removal rate, improving production cycle time

✔ Smooth chip removal, reducing the risk of tool breakage.

✔ The ball-nose cutter tip is less likely to chip, ensuring a more stable tool life.

✔ Easy to process curved surfaces, less likely to leave step marks.

✔ Better suited for material removal requirements in deep cavities and complex mold structures.

For machine tool operators, a ball-end mill that can consistently perform roughing, minimize tool changes, and prevent chipping is the most direct tool for boosting efficiency.

6. Support non-standard customization to ensure that the cutting tools better match the workpiece structure.

Modern machining processes are becoming increasingly complex, and many workpieces cannot be machined effectively using standard ball-end mills alone. To ensure both machining efficiency and tool life, HuaTuo Tools is capable of providing:

Customized non-standard diameters

Customized with special blade length and neck length

Special R Custom corner radius

Custom special coatings

Special-shaped tool manufacturing

OEM/ODM Mass production

Let the tool. 100% Adapt to the workpiece structure, rather than forcing the toolpath and machining process to accommodate the tool.

7. Why Choose HuaTuo Tungsten Steel? 2 End-mill cutter with a blade head?

From the perspective of user experience, the reasons for choosing it include:

Rough machining has high strength and removes material quickly.

Strong chip-removal capability, not prone to chip buildup.

The blade tip has high strength and is not prone to chipping.

Wide range of applicable materials

The ball-end mill is suitable for machining curved surfaces, cavities, and deep grooves.

Stable lifespan, reducing the number of tool changes.

High cost-performance, with overall costs more controllable.

Supports customization and offers greater process flexibility.

For machining workshops that prioritize efficiency, stability, and tool life, this cutting tool is a highly practical and reliable choice.

Recommended products